|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

At Texas A&M University, a team led by Peter McIntyre has developed a new design for superconducting cavities for linear colliders, perhaps even the International Linear Collider. Their polyhedral cavity design, which is only in its beginning stages and requires a significant amount of R&D, could offer such benefits as increasing the accelerating gradient and making the cavities more cost-efficient.

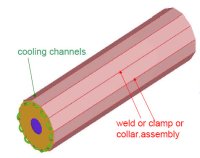

In the new design, the traditional smooth shape of the cavity is replaced by a polyhedral shape, made up of 12 contoured strips. Unlike traditional cavities, each one of McIntyre's cavities would be built as strings, not individual cells. To build each nine-cell cavity string, scientists would start with a continuous flat strip of niobium with copper on the underside and bend it into the contoured nine-cell shape. They would then bond the superconducting foil to a copper bar and cut it into a wedge. “What you've done is made a pie slice of a string of cavity cells,” McIntyre says. “Now you take the 12 slices and stack them around in a symmetric way to form a cavity.” Cavities are traditionally made of purely niobium, but the copper wedge on the polyhedral cavity is used to create a simple solution to complex problems. The idea of a cavity consisting of both niobium and copper originated at KEK in Japan. Stress produced by the fields can cause the cavity to deform, a problem known as Lorentz detuning. The copper backing provides a rigid support for the cavity that prevents such deformation. The cooling system in the new design also raises the potential for cutting costs. The helium cooling for the polyhedral cavity is provided by a closed-circuit flow in cooling channels through the copper wedge, so there is no need for totally immersing the cavities in superfluid helium--the currently practiced method. McIntyre explains that the polyhedral design would increase the current capacity of the cavity because it does not require welding. Current cavities are joined together by surface welds, which alter the grain structure of the cavity and lower the critical current. In the new design, however, metallic bands will hold the 12 pieces together, so no welds are needed. Also, if one of the 12 pieces gets damaged, it can be easily replaced. With the polyhedral design, there would be small gaps in the cavity where the slices fit together, but they do not interfere with the accelerating gradient and are very beneficial. In fact, McIntyre's team argues that these gaps help create a more focused beam and reduce the heat load. Scientists could also more easily clean and polish the inside of the cavity because the new design allows for open access to the interior surface. The surface could be inspected directly before assembly, which cannot be done with current cavity designs. The open access also provides an easy way for scientists to apply advanced superconducting layers to the inside surface of the cavity that would make linear colliders double or triple in energy for the same power being put in. McIntyre and his team have submitted funding requests to further develop and evaluate model polyhedral cavities. They are also seeking increased collaboration for the project. Currently, the only results the team has are from simulations and theoretical models, but they expect to have experimental data in a few months. While the new design may hold promise for future linear colliders, it will require further development and testing before it can be considered for the ILC. -- Amelia Williamson View slides: "Polyhedral Cavities for Linac Colliders," Peter McIntyre, Al McInturff, Nathaniel Pogue, and Akhdiyor Sattarov, Department of Physics, Texas A&M University |

|||||||||||||

| © International Linear Collider |