|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

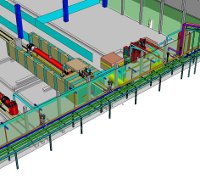

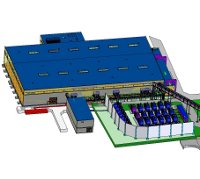

It takes vision to be able to image the transformation of one thing into another. Take a football field, for example. What are your associations – running, competition, goals, fun? And now imagine you want to build a new accelerator. What would you use the field for? The European XFEL team at DESY did not have to reflect for very long: acceleration, competition, goals? An accelerator module test facility of course! It’s only a small step to the next vision: an accelerator module test facility for the ILC… Let us begin at the beginning though. Like almost any lab, DESY is chronically short of space for its high-tech facilities and new projects, one of which is the European X-ray Free-Electron Laser, or European XFEL for short. A little over three kilometres long, the facility will accelerate electrons to produce X-ray laser flashes for science, using a linear accelerator based on the same technology as the ILC. Construction started earlier this year, and the laser is supposed to run from 2014. Before it can run successfully, all of its 100 accelerator modules and industry-produced niobium cavities must be tested under real-life conditions – meaning supercold. It so happened that the football field on the DESY campus sat not far from a few key facilities for real-life tests. “The test facility's location had to be very close to the cryogenic hall to make supply with liquid helium easy,” explains DESY's Bernd Petersen. It was a deal: the football field had to transform into a 4000-square-metre test hall. “It hurt to lose the field,” says Joachim Mnich, director for high-energy physics at DESY and keen footballer. “This is football-crazy Germany after all! My consolation is that, because the XFEL and the ILC are so similar, I hope we will be ale to use the hall for ILC-related tests when the XFEL is running.” Construction for the accelerator module test facility or AMTF started in July, when three politicians laid the cornerstone to the new hall on the field that had just been cleared of one metre of topsoil. The AMTF will be built as a major part of the DESY contribution to the X-ray free-electron laser and is supposed to start this job in 2011. All cavities and fully equipped accelerator modules for the European XFEL will pass through here before they reach their final destination in the tunnel. The hall will sport three test benches for accelerator modules, two vertical helium baths for the cavity tests and an area for testing and mounting the waveguides for the RF system. The cavities for the European XFEL need a lower gradient than those for the ILC, but their quality needs to be just as high. They will come from serial production in industry - a process that has many cavity experts on the edge of their seats because they hope to benefit from the potentially huge learning curve for serial production for the ILC, where 16 000 top-quality cavities are needed. For the tests, the cavities, which are already welded into their helium tanks, are dipped in liquid helium in bundles of four and test stands measure their accelerator field strength and quality are measured. When the XFEL cavities have passed this test, they are sent to CEA at Saclay in France where the final assembly of the around 100 modules takes place. When the finished modules return to DESY, they will go through a complete system check in the AMTF and are put to the test under operating conditions (expect for a particle beam passing through them) to check for vacuum and helium leaks and test accelerator field strength and thermal insulation. Every week, a module is due to return from CEA and go through a ten to fourteen-day test run before being equipped with waveguides. The design of the AMTF is based on an older design for a test hall for TESLA, the ILC's technological and spiritual predecessor. The goal was to test one quarter of the accelerator's modules – “otherwise the test hall would have had to be enormous,” explains Bend Petersen. ILC test facilities would probably do the same: severe tests for early production series with reduction to every fourth module later in the series. The test run would be practically identical. Currently there are no plans to hand the AMTF over to the ILC effort when the European XFEL is finished – the hall will belong to the XFEL company and it will be their decision how to use it. But with a little vision and hope – and good timing – it may be a welcome addition to test facilities existing or under construction in Japan and the US. -- Barbara Warmbein |

|||||||||||||

| © International Linear Collider |