|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

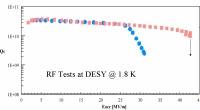

Last January, engineers from the DAPNIA laboratory in Saclay France qualified a new electropolishing facility for single cell cavities. Their first electropolished cavity reaches a promising result, above 42 MV/m (megavolts per metre) of accelerating gradient. It allows them to join the global R&D effort on these cavity treatments. Before they are used to accelerate electrons and positrons, cavities have to be meticulously polished and cleared. All these treatments improve the accelerating gradient a cavity can achieve. The cavity surface cleaning and smoothing chain includes mechanical treatments, buffered chemical polishing, electropolishing, high pressure rinsing and baking. At Saclay, France, the DAPNIA laboratory has been working on RF cavities for about 15 years, within the TESLA collaboration. They already had chemical and baking facilities, a class 100 clean room, and vertical and horizontal RF test stands. In October, they went one step further with the end of the construction of a new electropolishing facility for single cell cavities. For safety reasons, it took them time to be ready for tests, as manipulating such dangerous acid like hydrofluoric acid requires passing very strict safety checks. Electropolishing consists of having an acid bath flow through the cavity and applying an electric current (see NewsLine 29 June 2006). The first aim of the DAPNIA electropolishing team was to show they can achieve the same gradient that was obtained at DESY. This is why they started using exactly the same set of parameters, or “recipe”, and tested the cavities afterwards. DESY sent them a single cell cavity that was already treated and obtained good results (35 MV/m). After one and a half hours of treatment under a constant voltage of 17 volts, at about 30°C, they succeeded to dissolve 55 grams of niobium, which represent 42 microns removed. Then the cell was rinsed with ethanol, which dissolves sulphur, a non-desired by-product of electropolishing. Then the cavity was sent back to DESY where it was baked and tested. They measured a record gradient -for a TESLA type cavity- of 42.7 MV/m, which was 7 MV/m more than the last performance. The reason of this improvement is still under study. Was it due to the additional electropolishing treatment or a difference in the process? Only time will tell. “We were very happy to reproduce the DESY good performance in collaboration with them. We successfully passed the qualifications tests and we are now ready to participate in the global effort of electropolishing treatment R&D,” said Fabien Eozenou who was leading these tests at Saclay, with four other collaborators. The laboratory now contributes to the GDE's “S-Zero” R&D task force, whose goal is to demonstrate the required 35 MV/m acceleration gradient for the ILC. In the future, they will test different rinsing procedures, try different voltages and try to improve the acid recipe. “Our ultimate goal is to obtain the highest gradient with high reproducibility in safest working conditions and at the lowest cost”, said Eozenou. They will try to process cavities with new bathes tested on samples such as high hydrofluoric acid or high water concentrations. The work is supported by the European Community-Research Infrastructure Activity under the CARE SRF Joint Research Activity (see NewsLine 1 December 2005). It was carried out thanks to the GIS SUPRATech infrastructures and the financial help of the Ile de France Region. In the next weeks, ILC NewsLine will describe undergoing studies at the cavity baking facility of the same DAPNIA laboratory at CEA Saclay. -- Perrine Royole-Degieux |

|||||||||||||

| © International Linear Collider |