|

|||||||||||

|

|||||||||||

|

|||||||||||

|

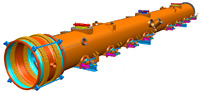

Using state-of-the-art technology, cryomodules are vessels that contain superconducting cavities in a linear accelerator. Inside the module, liquid helium cools the cavities to -271° C, only slightly warmer than the coldest possible temperature. The superconducting cavities operate at these super-cool temperatures, pumping more and more energy into the particles that are moving at nearly the speed of light inside the accelerator. Because the ILC will require 2000 cryomodules, the design team must consider two very important factors: manufacturability and cost. Achieving this perfect balance requires many design iterations, leading to several generations of cryomodules. Each generation builds and improves on the last version, moving closer to the right design for the ILC. While the 3rd generation cryomodule was manufactured and tested at DESY under the TESLA collaboration, an international team is already working on the 4th generation cryomodule for the ILC. "The 3rd generation cryomodule was made to demonstrate the state-of-the-art in manufacturing of the cryostats, but for the ILC we need a very large number of these units, requiring a study of all the details of the design," said Vittorio Parma of CERN. "We need to have a design concept, which can be produced in large numbers and keeping cost reasonably low." The 4th generation group proposes moving the quadrupole magnet from the extremity of the chain of cavities to the centre of the cryomodule for stability reasons. The magnet will sit beneath one of the three supports, becoming a centre post in the most stable position of the vessel. Limiting movement inside the cryomodule is extremely important for maintaining a stable, steady beam line – a very delicate matter in a linear accelerator. Parma explained that another important improvement is increasing the real estate gradient in the cryomodules by reducing the inactive space between the cavities. For the ILC, each cryomodule will contain eight cavities, linked together in a chain by mechanical interconnections. "Wasted space in terms of accelerating the particles, makes the cryomodules longer than what they can ideally be. A longer cryomodule results in a longer tunnel and higher costs. By reducing the cavity space by 1 centimetre, the entire tunnel would decrease by 200 metres." he said. Changes in the cryogenic system are also leading to major redesigns for the 4th generation cryomodule. Based upon the experience of engineers working on the Large Hadron Collider at CERN, the 4th generation cryomodule for the ILC will require larger diameter piping inside the vessel. "The arrangement of these pipes in the cryomodule must change considerably," Parma said. "In the 3rd generation cryomodule, the pipes were small, and now we have made them much bigger because of the cryogenic requirements. This requires some engineering work to be done." Just like the ILC project, the 4th generation cryomodule design team is a global effort. Approximately 30 members of the team met at CERN in January to discuss the latest cryomodule design. Scientists from CERN, DESY, Fermilab, INFN, JLab, KEK and SLAC all attended the meeting. "We had a strong U.S. and Italian participation, but all of the labs were represented," Parma said. "And KEK expressed a lot of interest in producing cryomodules." In a future issue, NewsLine will report further on the cryomodule work that is happening at INFN and KEK. The 4th generation cryomodule design effort will continue for the rest of 2006, with a complete drawing package ready to be sent out to vendors by the end of 2007. From that point, it will take approximately one year to assemble the first 4th generation cryomodule at Fermilab. Ultimately there will be a 5th generation cryomodule, which scientists expect will be a prototype for the ILC. -- Elizabeth Clements |

|||||||||||

| © International Linear Collider |