|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

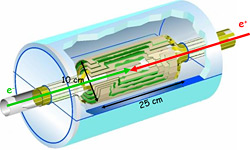

At the heart of the massive ILC detector system, the vertex detector, a compact tracking device about the size of a wine bottle, surrounds the interaction region. This high-tech piece of equipment hosts about a billion pixels in total - equivalent to hundreds of the finest cameras. It works just like a 3-D camera because it measures the tracks of outgoing particles with micron precision. "Building and designing a vertex detector for the ILC is a real challenge," said Marc Winter, a physicist leading a micro-electronics group in IPHC, an IN2P3 Laboratory in Strasbourg, France. "This detector will reach fantastic performances, well beyond what was ever achieved so far." Thanks to its high luminosity, to well defined interaction parameters and to operating conditions which are much less demanding than for hadron colliders, the ILC allows for an unprecedented sensitivity to physical processes. Taking advantage of these experimental conditions, physicists will try to scrutinise phenomena involving very short-lived particles, such as taus, cousins of the electrons, and charmed particles, made of c-quarks. They fly over distances as short as a few hundred micrometres from the interaction point, before they decay into secondary - more stable - particles, which can be detected in the apparatus. Reconstructing the decay vertex from these particles requires an outstanding spatial resolution, provided by a high precision vertex detector. This resolution has to be complemented by a very light and thin material budget, ensuring that particles traversing the detector will only be slightly affected by a phenomenon, called "multiple scattering." (When a particle passes through the detectors, each particle interacts with the material, which makes it change direction - they ‘scatter’- thus fooling the reconstruction of their spatial origin.) The ILC detector community considers the pixel technology mandatory for achieving this goal. Composed of semi-conductor material, each tiny pixel is read out individually in order to preserve the high-precision space point it provides, accurate to a few micrometres. The detector will be covered by up to one million pixels per centimetre squared. Located very close from the interaction point - slightly more than a centimetre - it allows reconstructing accurately secondary vertices. An intense background in the vertex detector mainly comes from electromagnetic interactions between the two incoming beams, called "beamstrahlung." The result is an overwhelming electron and positron cloud, which fires several thousands of pixels every microsecond. A major technical challenge is then to read out hundreds of millions of pixels ten thousand times per second, if not more, to avoid saturating the detector. The beamstrahlung electrons and positrons also generate radiation damage when traversing the pixels. The detection performance depends on the special care taken to make the pixels radiation tolerant. The choices for the detector geometry and pixel technology are still not frozen. For the geometry, a lively debate takes place. The two options are a fully cylindrical detector (see figure) and a shorter cylinder complemented by disks in the end-caps. For the pixels, various technologies are being developed: CCDs (Charged-Coupled-Devices), CMOS (Complementary Metal Oxyde Semi-conductor) sensors, and DEPFETs (DEpleted P-channel Field-Effect Transistors). A very active community of physicists and engineers tries to push the performances up to their extreme limits. They aim to achieve – simultaneously - the required high granularity, low material budget, fast read-out, satisfactory radiation tolerance and low power consumption. "It seems unlikely that none of the technologies under development will satisfy these major requirements," said Winter. "We are now in a process aiming to make at least one technology reach the high performances needed to tackle the phenomena at the heart of the ILC physics programme." -- Perrine Royole-Degieux |

|||||||||||||

| © International Linear Collider |