|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

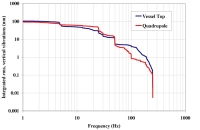

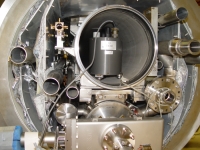

Not all vibrations are good. With their 600 nanometres in width and only 6 nanometres in height, the ILC's particle beams could easily be veered off course if parts in the accelerating modules, for example the final focus quadrupole, moved by only a few nanometers. Monitoring and feedback systems will make sure that this doesn't happen, but it's even better to identify weak - moving - points and eliminate them from the very beginning. “The whole point is that the machine must work beautifully,” says Ramila Amirikas, part of the vibrations studies group at DESY. “Our job is to show that the quadrupoles will be stable or suggest ways to improve them if they aren't.” They have performed lots of tests on modules for FLASH to learn more about the future European X-Ray Free-Electron Laser XFEL, and their results are equally important for the ILC whose modules will be extremely similar. While the XFEL will be suspended from the tunnel ceiling, the ILC will stand on the ground. But it's not so much the 'cultural' noise (natural ground movements, vibrations caused by industry or traffic close to a site) that they are tracking but the floor noise that drives internal resonances within the modules. “Nevertheless it's preferable that a site does not have high cultural noise content of course. Our team has already collected lots of ground vibration data on many different sites,” says Amirikas. With the ground vibration data and the knowledge of internal movements they can predict very precisely how the machine will move at any given site. “We measured the mechanical transfer functions from 0.03 Hz to 400 Hz from the ground to the cryomodule vessel and from the vacuum vessel to the quadrupole along 3 axes,” explains her colleague Alessandro Bertolini. “By combining the information from the mechanical transfer function measurements with the natural ground motion and facility noise at any site, is possible to estimate the quadrupole vibration level wherever the cryomodule will be installed.” Studies show that the way a module is supported is crucial. One set of measurements made on a module supported by girders that stood on concrete showed huge peaks from internal resonances of the girders that were also detected inside the module. Other tests compared suspension by rods with suspension by bolts (with the bolts winning that one) on a suspended module. The most recent tests on module 6 were made while it was in the new test stand. "We were especially interested in possible movements of the quadrupole that sits at the very end of the module," explains Amirikas. She and Bertolini attached seismic sensors and geophones, devices that detect movements in the nanometer range, to the quadrupole, to the gas return pipe inside the helium vessel and to the top of the vessel. The test series at room temperature showed relative displacements of the sensors within 20 percent (See figure caption). The team has just ended a series of vibration measurements at 2 K with geophones placed on the quadrupole inside module 6 which can measure at these low temperatures. The vibration detected by these geophones is directly compared with geophones placed on the vacuum vessel which are at room temperature. The group is also contributing to the design of the type-IV module for the ILC by collaborating with a vibration studies group at Fermilab. Another big excitement for the team will be the new 50-metre XFEL mock-up tunnel where engineers and technicians will dry-run the installation of the XFEL. Vibration studies have been included from the very beginning. “We may learn a lot from these studies not only for the XFEL, but also for the ILC.” says Amirikas. -- Barbara Warmbein |

|||||||||||||

| © International Linear Collider |