|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

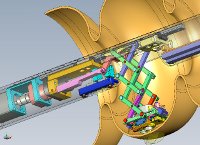

The inner surfaces of the niobium cavities for the International Linear Collider have to be polished to literally sparkle, since the smallest defects, such as bumps, pits, welding flaws or human-induced scratches on them are considered to be dominantly responsible for the deterioration of the cavity performance and can even lead to quenches and field emission. Many techniques and technologies have been studied and developed already to address this challenge. At the end of November, the first prototype of a new gadget developed with different approach was delivered to KEK. This new gadget, called the inner surface grinder, allows the scientists to pinpointedly grind a part of cavity surfaces to remove offensive defects. “The technology to grind the inner surface has been around for twenty-five years,” said Hitoshi Hayano who designed this machine. “However, there was no way to tell how far you should grind the surface to make it smooth with the technology at the time. The effort to physically grind the inner surface did not lead to performance gain, and it was regarded as an ineffective technique.” Now, scientists have a technology to take a look inside the cavity with the "CavCam", the high resolution camera to inspect the cavity's inner surface, identifying the numbers, locations, shapes and sizes of those defects. “If you see a bump on the surface, you're going to want to get lid of it, right?”, Hayano smiled. In the first prototype of the inner surface grinder, the grinding work is performed with a "polymond" diamond-powder filing sheet, which is cut out by a punch press to approximately five millimetres in diameter, attached to a tip of the small motor. This bitty filing machine will be extended by a pantograph mechanism, press against the defect, and with excentric circular motion, grind the surface gradually and carefully until it's fine and smooth. This assembly can be retracted inside a stainless-steel pipe of 50 millimetres in diameter, when the grinder is initially inserted into a cavity. “The biggest challenge was downsizing the whole machine to fit into the cavity,” said Ken Watanabe, a postdoctoral fellow at KEK, who is working on this project. The machine needs to have a rigid body to endure pressure and mechanical vibration. At the same time, the machine needs to be equipped with a micro-camera and small nozzles for spraying and sucking water for wet grinding. The scientists worked with SDL, ltd., a small company with five employees located in Osaka, to develop this machine. “We provided them with a rough sketch in the middle of September, and we received the prototype in November,” said Watanabe. “We are planning to conduct a series of tests to evaluate the operational safeness, aiming for the application on the real cavity early next year.” If this turns out to be successful, this type of gadget could significantly improve the cavity performance yield and will reduce the overall cavity production cost, since a defective cavity does not need to be thrown away. “We are accumulating data to evaluate the effectiveness of this machine,” said Watanabe. The gradient tests on two STF baseline cavities manufactured by Mitsubishi Heavy Industry, Co., ltd. will be done three times each by March next year. “We will attach the thermometer to the identified defects' location. We already know the shape and size of those defects. We are expecting to find out more, and looking forward to have chances to try the machine.” -- Rika Takahashi |

|||||||||||||

| © International Linear Collider |