|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

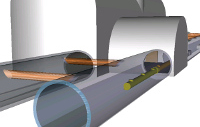

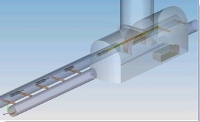

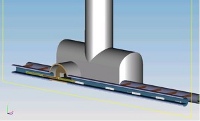

In order to have a detailed and visual model of the ILC tunnels, shafts, accelerator components, beam pipes and support lines, a team from around the world has just shown that they can produce three-dimensional ILC models. These will be crucial for efficient future planning and integration and will now be extended to other areas than the one of the sample exercise.

Scientists like to believe that the language of science is universal – definitely that of mathematics and engineering. The conventional facilities and siting group (CF&S), a global team made up of some six different nationalities, has no language problems when its members exchange ideas at teleconferences or sit over technical drawings at meetings. Apparently, however, the common engineering language does not extend as far as to the software applications they use. When they attempted to merge their regions' modelling software packages, it became clear that a bug in the exchange of coordinates had misplaced the accelerator in the tunnel envelope, giving the ILC a completely new (if unwanted) design. They have now successfully married the different computer-aided design or CAD systems in the engineering data management system (EDMS) to come up with a uniform three-dimensional model for the underground tunnels derived from the data generated by the CAD systems. Software and EDMS expert Lars Hagge from DESY pulled it all together. “Incongruent or faulty parameters are much more easily spotted in 3D,” he confirms. “Sometimes, with the help of a complete 3D model, you can see potential problems that you might not have thought of before – space for escape routes and transportation options, or interference between supply lines for example.” Accelerator cryomodules may be the most important tunnel element for the physics the ILC will produce, but they are by far not the item in the tunnel that takes up most space. Using the ILC EDMS, the group first integrated the models produced by three different CAD systems and then exported it all to the EDMS, where everybody can look at and play with them. Modifications, however, should only be made by the original authors to avoid confusion and incompatible parallel versions. Different groups have to talk to each other to get from physics requirements and accelerator lattice to engineering concepts and finally a fully detailed model showing all components. The CF&S team picked a tunnel region that is especially challenging and diverse – the point where the main linac goes over into the beam delivery system, some two-and-a-half kilometres away from the interaction point. It all centres around a shaft – Shaft 3 to be precise – and looks at the tunnels regions 50 metres in each direction from this shaft. “We've got many things going on in that area, that's why we chose this particular section,” explains John Osborne from CERN. There is the magnet and accelerator setup (also called lattice) of the main linac, there is the different lattice for the beam delivery system, waveguide tunnels every 12 metres, main and service tunnels and a service cavern complete with mobile shielding that blocks out radiation from the main linac during operation but can be slid back into the cavern for servicing. Different information came from different labs: the beam delivery system model (in Solid Edge) from SLAC, the linac model (in I-deas) from Fermilab, the tunnel (in CATIA V5) from CERN. “We will have to work with the various systems to come up with a fully integrated model,” says Hagge. The team's next exercise: the positron and electron source, the technical infrastructure and the damping rings. Eventually the EDMS will have a 3D model of all technical areas of the ILC – a first glance at a future machine! “I would never have thought that integrating models from all these different labs could be done so quickly,” says Ewan Paterson from SLAC. “It shows that we will be able to work with well-developed 3D models of the ILC soon!” -- Barbara Warmbein |

|||||||||||||

| © International Linear Collider | |||||||||||||