|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

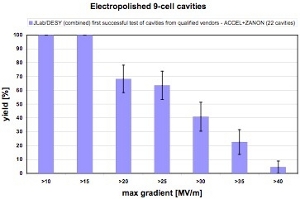

The idea sounds simple enough: collect all the data that exist in the world on cavities – nine-cell TESLA-style cavities, to be precise – including all tests, manufacturers and achieved gradients and merge it into a common format so that all cavity professionals around the world can extract the data they need to compare cavity performance and learn. Anyone who has ever set up a database and tried to merge existing data sets into one knows: it's not that easy. However, the ILC's accelerator experts have just decided that they will all use a database system developed by DESY to set up the world's first global cavity database. The main driver behind this is a key ILC challenge called ‘yield’ — an efficient word for a concept that means something like 'the probability that cavities will reach the required gradient'. 'Gradient' in turn means the energy imparted by a cavity to electrons or positrons over the distance of one metre — a challenge at the heart of the ILC, because a high gradient means efficient acceleration, which means short accelerators, which in turn means lower cost. Only good statistics give a good picture of the yield. “That's why we are really after statistics, we need this standardisation to be able to compare data from around the world and provide reliable estimates of expected cavity performance,” says Camille Ginsburg from Fermilab, who is in charge of the ILC cavity database project. The ILC cavity-treating labs (Fermilab, JLab, Cornell, DESY and KEK) agreed in July that they would use the DESY database system (developed by Dieter Gall and Vladimir Gubarev), and data from 76 cavities have been entered so far into a temporary location for uploading — from their production name (TB9ACC011, for example) to all the radiofrequency tests done in the last years to surface treatments. Based on these data, you can apply 'cuts' — for example only look at data from specific manufacturers on electropolished cavities produced with fine-grain niobium after the first test. The database would tell you that at a gradient of around 15 megavolts per metre, you'd have a 100% yield — all cavities work. If you go up in gradient, however, the yield goes down. Studying the effect on the yield by varying the cuts provides guidance for cavity manufacturer development, cost studies and R&D for cavity treatment. Eventually this could lead to improved understanding about niobium handling or cavity surface treatments, “but we are not using the database for R&D purposes just yet,” says Ginsburg. All cavities for the European XFEL will be included into the database as well as their performance and characteristics are so similar, even though the gradient they are required to produce is much lower — 25 MV/m as opposed to 31.5 MV/m for ILC operation and 35 MV/m for ILC tests. The team expects to add data from some 16 additional cavities by next summer and learn more about yields and cavity production along the way. -- Barbara Warmbein |

|||||||||||||

| © International Linear Collider |