Setting the stage for a particle collision event requires orchestration of Wagnerian proportions.

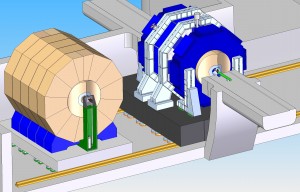

Part of the production for the International Linear Collider involves perfectly positioning giant, unwieldy detectors in the particle beamline to capture data from electron-positron collisions. Recently ILC collaborators agreed that steel-reinforced concrete platforms would be used to steadily and nimbly move the ILC’s two detectors, ILD and SiD, into and out of the beamline.

“We finally established it clearly,” said Vic Kuchler, head of the ILC Americas Conventional Facility and Siting (CFS) group and coordinator of the global CFS effort. “That was a big deal.”

It was a big deal in more ways than one. The platform decision set the course for designing the detectors’ moving mechanisms. It also helped establish domains of oversight in the detector hall, the layout of which requires expertise from separate areas – accelerator science, civil engineering and detector research.

Members of these groups came together in Paris last May for an auxiliary meeting to an ILD (International Large Detector) conference. They established that the CFS group, which manages civil engineering matters for the ILC, would take ownership of the platform design.

The ILC scheme calls for two detectors, ILD and SiD (Silicon Detector), each of which takes weeks-long turns in the beamline to get face time with the collisions.

There is no precedent for such regular detector switch-off. Particle colliders often use permanently positioned detectors at the points where particle beams intersect. At the Large Hadron Collider, for example, four detectors are situated around the 27-kilometre ring, one for each interaction point. All take data without interruption.

“The unique thing about the linear collider is there’s only one interaction region,” said Philip Burrows of the ILC Machine-Detector Interface group. When one detector’s turn is up, it’s pulled out of the beamline and the other is pushed in. “The push-pull aspect is new.”

Using a platform to push or pull the detector ensures its in toto movement whenever it has to make its move.

“The ILD is made up of five modular slices. A platform transport system naturally maintains their relative alignment,” said Tom Markiewicz, member of the ILC Machine-Detector Interface group.

For simplicity, scientists decided both ILC detectors would make use of platforms.

Researchers would be able to draw on LHC experience with similar transport mechanisms.

“We chose the concrete platform because we saw that it worked with CMS,” said John Osborne, ILC European leader for CFS, based at CERN. The CMS (Compact Muon Solenoid) detector at the Large Hadron Collider uses a concrete platform to pull it offline.

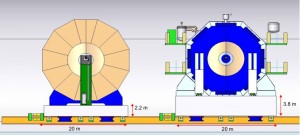

The difference in size between the ILD and SiD detectors necessitates different designs for a platform.

As a foundation for the detector, tonnes ride on its reliability.

When the detector is online, it must be perfectly axially centred on the beamline to take clear pictures of the collision event. Its platform must act like the world’s steadiest tripod, insensible to the slightest vibrations in the earth or in surrounding structures. When it’s pushing the detector into the beamline, it has to behave like the world’s smoothest, most obedient freight train, coming to a stop to within a millimetre of its mark. For platforms as big across as a humpback whale, that’s a tall order.

“Being even a few millimetres off can make a dramatic difference,” Osborne said.

A further complication is the two different sizes of the detectors. ILD is heavier and taller than SiD, so a single platform design can’t be applied to both.

“Since the detectors are different, it’s a challenge to make sure everything fits together,” Kuchler said. “In spite of the differences, you have to be able to back one detector out, move the other detector into position and get the collider running again fairly quickly so you can maximise data collection.”

The linear collider community invited a UK-based global engineering firm, ARUP, to propose platform schemes that take into account all these concerns. They will also produce a three-dimensional geotechnical model of rock behaviour, initially tailored for CERN molasse rock housing the proposed Compact Linear Collider, but which could be adapted for other ILC regions at a later date. The company is expected to deliver their proposed designs by the end of 2011.

“The idea that you have 10- or 15-thousand-tonne detectors that you roll in and roll out again several times a year, getting them back to where they were within a millimetre – that is, from an engineering perspective, a phenomenally challenging idea,” said Burrows. “Still, I don’t know of anybody that thinks it can’t be done.”

Nice article. Just a remark, CMS at CERN does not move on a platform offline. A concrete platform, very similar to what proposed for ILC detectors, has been used for lowering the experiment down to the underground cavern in 2007.