Kamaboko is a type of Japanese fishcake with a distinctive loaf shape, usually served sliced thin with dipping sauce such as soy sauce and wasabi or as a topping for noodles. So what does kamaboko have to do with the ILC? It is the shape of the newly proposed ILC tunnel design for an Asian mountain site.

On 12 and 13 October, a meeting was held at KEK to discuss conventional facilities and siting (CFS) issues for the ILC.

When the Global Design Effort (GDE) released the strawman baseline 2009 (SB2009) with an effort to optimise cost and design, the single-tunnel design was adopted over the double-tunnel design proposed in the Reference Design Report (RDR) in 2007, where a service tunnel lay along the accelerator tunnel. At the time of SB2009, scientists at KEK proposed a so-called SB2009-J single-tunnel design, which looked as though it had two tunnels.

The Japanese ILC CFS team has been working on detailed site analysis in cooperation with specialists from industries on eight different variations for the ILC tunnel design, ranging from the RDR-type double tunnel to a proposed new shape. “As a result of hard work done by the Japanese CFS team, we would like to introduce this kamaboko shape as a new ILC tunnel design for mountain regions,” said GDE Project Manager Akira Yamamoto of KEK.

“We have examined the single-tunnel design that fits Japanese candidate sites for SB2009 based on an excavation method using the tunnel boring machine (TBM),” said Masanobu Miyahara, a technical administrative specialist at KEK. However, the SB2009 tunnel design for the Asian site was not really a single tunnel. “You will see two tunnels on the blueprint of our single-tunnel design for SB2009 because it is a rather common practice in Japan to excavate a pilot tunnel along with the actual tunnel in the case of large-scale construction,” said Miyahara.

TBM is one major tunnel excavation method. Another is called the new Austrian tunnelling method, or NATM. Because every particle accelerator needs stable ground for construction, TBM, which is generally better for providing stability, was the choice for ILC tunnel construction in all three regions of the Americas, Asia and Europe.

A TBM is a cylinder-shaped boring machine that grinds through different types of soil, from hard rock to soft ground. This method is especially well suited for use in solid rock, having the advantages of limiting the disturbance to the surrounding ground and helping to produce a very smooth tunnel wall. TBM is also effective in construction projects that need to be done quickly.

“During TBM construction, the giant machine will stay frontline and constantly grind the soil through days and nights. If the TBM hits a big groundwater flow or fracturing rock, it can be very troublesome,” said Miyahara. “Since about 70 percent of Japanese land is covered by hills and mountains, it is often the case for tunnel construction in Japan to excavate a smaller pilot tunnel to collect necessary geological information in advance.”

Without geological information, miners can face dangerous situations such as sudden flooding or cave-ins. And even if they avoid fatalities, nonfatal accidents would require a long recovery time, which would result in construction delays.

Could NATM do any better than the tunnel boring machine?

“For the RDR and SB2009, we excluded NATM as a construction method option because of its slow excavation speed, which averages 120 metres per month. It would need a few times longer construction period compared to TBM,” said Miyahara. “But we found out that if we optimise the construction schedule by NATM, we can reduce the construction period much more, to an even shorter time than that using TBM. If we schedule the tunnelling well, constructing many parts of the tunnel in parallel, construction can be done much faster and relatively cheaply.”

With NATM, the tunnel is excavated by a blast-and-drill method. Usually, shotcrete is applied onto the tunnel walls shortly after excavation, constituting a shell. Unlike TBM, where the tunnel cross-section shape is always circular and the diameter of the tunnel depends on the size of the machine, the shape of the NATM tunnel can be very flexible, making it possible to make a kamaboko shape.

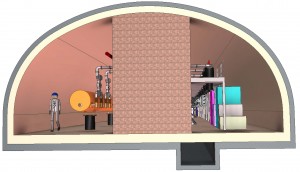

The kamaboko tunnel is about 11 metres in width and 5.5 metres in height, divided into two rooms by a thick concrete wall. At the CFS meeting, Toshiya Sanami, radiation specialist at KEK, reported the new design’s radiation safety analysis. According to the study, the kamaboko tunnel with a 3.5-metre-thick wall in between two rooms can ensure same level of safety as that of the RDR two-tunnel design.

Also, NATM can help realise significant cost savings. “The biggest drawback of TBM construction is the cost of the machine. The excavation equipment used for NATM is much cheaper. We can deploy many machines at the same time, excavating different parts of the tunnel at the same time,” said Miyahara.

“We can also omit pilot tunnel construction,” he said, stressing the benefits of construction by NATM. “By NATM, excavation equipment is positioned posterior to the front of construction, so if any incident such as flooding occurs, workers can take a flexible approach with various auxiliary construction methods. This is a big advantage for construction with the tight schedule of a project such as the ILC.”

The design presented at this meeting was for the main linac tunnel, but the flexibility of NATM construction will be beneficial for other tunnels with much more complicated shapes, such as the beam delivery system, the electron and positron source, the damping ring or the central region of the tunnel including the detector hall.

“I am very pleased to report a possible cost reduction of more than 10 percent compared to that of the RDR design,” said Yamamoto. This is the first detailed analysis done for the tunnel design together with industrial partners. The same kind of study is under way in the Americas and Europe.

Recent Comments