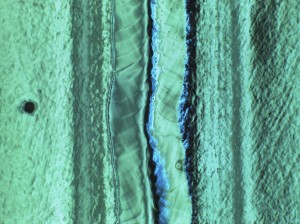

This 'crater' on the left hand side of the picture would almost certainly lead to a quench very quickly. The 'Kyoto camera' spotted this spot on a cavity's interior surface. It's a remnant from the production process that couldn't be eliminated during surface treatment, which led to the chemicals reacting with the surface in a different way than normal and causing the crater. In fact the cavity quenches at 13 MV/m.

Everything has a limit—superconducting cavities are no exception. Physicists put voltage in their superconducting cavities to boost the energy of particles. But it’s possible to ask for too much from a cavity. When this happens, the cavity fails: the superconducting material becomes normal conducting, the voltage collapses and the energy escapes. This is called a quench.

Even if a cavity is flawless, it will quench at a certain point. This limit is based on the material properties of the cavity. It’s believed to be the point at which the strength of the magnetic fields produced by the electric current is simply too much for the cavity to handle. As a result, the metal changes phase from super- to normal-conducting. To get the most from their cavities, physicists try to get as close to this limit as possible without quenching. “We rarely reach this theoretical limit,” says Jefferson Lab scientist Rongli Geng. “Although we’re getting close.”

More often quenches occur because of tiny defects that become part of the cavity’s surface during handling. One is the inclusion of normal-conducting material, such as a microscopic speck of copper or iron. These areas cannot conduct as efficiently as the superconducting niobium, and so they will release energy as heat. This little swell of heat can spread, causing other areas to overheat and lose their superconducting power. (Remember, superconducting material needs to be kept very cool in order to carry current efficiently.) To fix this, scientists must try to improve the conducting powers of the surrounding niobium. This way when a problem spot’s temperature begins to rise, the surrounding metal can carry away the excess heat.

A second problem comes from imperfections in the cavity’s surface such as a hole or bump. Once again this spot creates a heat pulse. In this case the defect disrupts the current’s flow, like water encountering a rock in a river, causing the current to change directions and build up extra energy that is released as heat. Luckily, with intensive polishing it’s possible to reduce these surface defects, and precise inspection methods can identify possible quench inducers on a cavity surface before they become a problem.

Because cavities differ from another, physicists need to characterise each to understand how and when it will quench. Some, for example, might quench at 20 megavolts per metre (MV/m), while others could reach an impressive 40 MV/m. Ultimately, ILC scientists aim to have more than 90 percent of the collider’s cavities capable of supplying 35 MV/m of acceleration to particles.

Recent Comments