As a global science project, the ILC draws on the resources of laboratories in the Americas, Asia and Europe. It also calls on capabilities from industrial factories and plants around the globe.

The ILC Global Design Effort (GDE) has worked to encourage an open exchange of information and ideas among these diverse collaborators and industrial partners to foster innovation, to keep project costs under control and to ensure industrial newcomers have ready access to information.

“We work on a multilateral basis,” said GDE Project Manager Marc Ross. “That’s key to everything the GDE does – a multilateral basis on more than one level.” At the level of laboratory-industry relationships, this has led to a choice to distribute R&D not to one business, but to several.

Project Managers Marc Ross and Akira Yamamoto at the Toshiba company in Japan. They stand in front of a display case of magnet windings and a test cavity. Image: Akira Yamamoto

The GDE has been actively cultivating partnerships with industry since 2009, communicating regularly with participant companies about their R&D in accelerator technology and bringing new companies into the community.

By encouraging multiple companies to develop, say, effective accelerator cavities, the GDE creates plural opportunities for science and technology innovation. That benefits the ILC while reaching beyond accelerators to other areas of science, says Project Manager Akira Yamamoto.

“Current technology may not be smart enough to open new physics. That’s why you need to innovate. What comes out of this is very nice science. Even if it might not be directly high-energy physics, in and of itself, it is science.”

The new science that springs from ILC research could be a better understanding of the physical properties of niobium or an eco-friendly method for polishing it. The scientific benefits of those kinds of breakthroughs aren’t limited to large, underground particle machines. Other fields of science can profit from ILC-fostered research. So could industry.

“Suppose accelerator-driven subcritical systems become a method for producing power,” said Fermilab’s Bob Kephart. “All of the sudden a cavity manufacturer has a market that’s in the energy production business.”

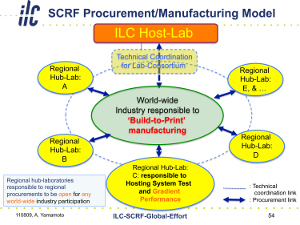

Industry is at the center of the GDE management model. Any hub laboratory can access any industry around the world. Image: Akira Yamamoto

Part of the intent of working with multiple businesses is to keep the competition broad. This accompanies a GDE effort to be reasonably transparent, making the community’s bigger-picture progress available to everyone. Encouraging research in the direction of decentralisation helps keep competition open when it’s construction time.

Also, spreading the research around is, for the GDE, simply practical given the large scope of the ILC’s research activities.

“It’s better to distribute the research and development effort to multiple companies, rather than to one (or two),” Yamamoto said. Superconducting radiofrequency (SRF) technology, perhaps the most significant advancement to come out of ILC research, is a relatively young field, so the majority of businesses that develop SRF components are on the smaller scale, not large assembly-line plants. By distributing the weight of production to multiple companies, the GDE parcels tasks at a scale – 200 cavities instead of 1,000 – that these reasonably compact or medium-scale businesses can ably manage, both in cost and labor.

For the ILC, this distribution also means built-in redundancy, a kind of insurance policy. In the event that one vendor’s cavities cannot meet specifications, there are other industrial sources to fill the gap.

“There should be no need to carry a large risk factor,” Yamamoto said.

Industry representatives meet with scientists at a recent ILC-sponsored satellite meeting of the SRF2011 conference. Image: Akira Yamamoto

Keeping multiple companies in the mix is fitting given the nuts and bolts of high-energy physics machines. While colliders are large, their parts are not. A few people can pick up an accelerator cavity unit and handle it without heavy crane work. So long as the components fit together when it’s constructed, the separate parts don’t have to come from a single company. Quite the contrary, the different parts would almost certainly come from different sources.

“It’s basically segmentable,” Ross said. “The nature of the technology is such that the slicing could actually work. If the linac is made of one type of cryomodule at one end and another type at the opposite end, we don’t care as long as they can be connected to one another.”

The GDE takes advantage of the ILC’s segmentability to explore technologies that are so-called plug-compatible.

“You can go to the store and buy a replacement part for your automobile that isn’t made by the company that made the automobile, just because they have standards,” Kephart said, explaining the concept of plug-compatibility. “That’s the strategy here – you want to make functionally equivalent parts produced in different parts of the world.”

The ILC’s open door to different suppliers doesn’t imply that companies’ innovations are written in an open book. Companies’ innovations belong to them. Yet should the issue arise, the GDE would work to protect company interests while maintaining its own intellectual property rights so that, in the interest of science, others can share in the innovation.

The hope is that a multilateral management approach to designing the collider brings innovation to high-energy physics, both in the proliferation of new technologies and in project management.

Thirteen companies participating in ILC research were represented at a satellite meeting of the recent SRF2011 conference. View their presentations.

Recent Comments