The two detector designs for the ILC are now elaborated by the ILD and SiD groups toward the Detailed Baseline Design Report (DBD). When the Letters of Intent (LOI) were called in 2007, the guideline said, “The LOI will not represent any formal commitment of the groups signing it to the project or to the proposed detector.” LOIs are meant to demonstrate the feasibility and capability of achieving physics goals of the ILC, and new ideas on detectors remain open. Nevertheless, the validated groups are striving to advance their detector designs to reach a good starting point for the time when the project is realised. One of the work plans for the DBD is to make a more precise estimation of the detector cost as it is, together with the technical aspects, one of the crucial features of the feasibility study. In general, the performance of a detector tends to correlate positively with its cost. Naturally one wishes to obtain the best possible performance with least cost. This motivates R&D of detector technology and leads to innovations. But at a certain point, one has to make a balance between them, and how to accomplish this depends on the physics aim and design strategy. The choice of technology and/or material and the size of each component are all taken into account. Finally a choice is made to match the ultimate purpose and affordability. There can be differences between groups and it is an advantage that we can compare the two strategies taken by the ILD (International Large Detector) and SiD (Silicon Detector).

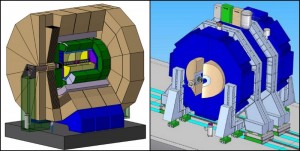

The two detector design groups ILD (left) and SiD (right) are working towards a precise estimation of the detector cost to be released in the Detailed Baseline Design Report.

When we wish to compare the two cost estimates, they should be prepared in such a way that allows meaningful comparison. The International Detector Advisory Group (IDAG) recommended last October that the costing of the two detectors needs coordination so that the two groups use the same methodology for costing. Such an attempt already existed during the LOI preparation. The funding schemes and commercial customs are different from region to region or country to country. Considering these large differences, the costs in the LOIs are coordinated reasonably well but not completely. IDAG pointed out that this situation needs to be improved.

In order to establish costing coordination and unify methodology, we formed a small working group composed of representatives of the two groups and an advisor from outside who is an expert on the costing of the ILC accelerator. The accelerator team has been working on the same problem for a long time and they already have a good solution for how to coordinate various differences among the regions.

The two detector concepts take somewhat different approaches for the cost-performance optimisation. Although it is a subtle one, they may affect the final designs. The SiD uses extensive analytical cost-performance optimisations. On the other hand, ILD tries that partly because of many options being considered. To see the consequences of this difference, if any, we have to coordinate the ways of costing more precisely. We also have to make many simulations, including collisions at high energies, to evaluate the detectors’ operation, helping to determine what works for effective detector performance. This exercise will give us valuable information regarding cost versus performance.

The costing working group has agreed already on several points, such as items to include in the cost and how to categorise them. They also agreed to use common unit prices for cost-driving raw materials. The work is still being continued for improvement, which will take more time.

The world economy is changing rather rapidly. This can cause uncertainty in the estimated cost after it is made for the DBD, which will use 2012 prices. For instance, the prices of iron and tungsten in the coming years will affect the cost. Also, the fluctuation of the exchange rates among different currencies is a big factor that may cause difference in the costs. However, once the methodology is clear, one can trace the shift in cost due to these factors.

When the time comes for real construction, most components will be produced by participating institutions at home and will be delivered to be assembled on site. In such a scheme, we hope the currency exchange rate does not matter so much as it appears on paper. More important is that we strive for such a day. And the costing exercise is one of the steps to achieve our goal.

Recent Comments