|

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

Physicists and engineers already know most of the empirical recipes to build very good accelerating cavities: highly pure niobium is essential, welding needs to be carefully controlled and surfaces undergo advanced cleaning and annealing procedures. But, as for every complex system, a lot of phenomena remain unexplained. The theoretical limits of RF superconductivity are not well known, and engineers also meet practical limitations to reach high gradients. Accelerator experts work very closely with material scientists to understand cavity properties better.

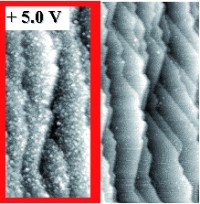

“Everything happens in a thin slice of less than 100 nanometres,” says Claire Antoine, materials physicist working at Dapnia in Saclay, France. In superconducting niobium, the electromagnetic field stays in a surface layer where the density of current can reach several 109 amperes per square metre (A/m2) and the electrical fields can reach much more than tens of Megavolts per metre (MV/m). In radiofrequency mode, the surface resistance of superconducting niobium is not zero. Still it is as low as a few nanoohms about 100,000 less than copper - but every defect might give rise to some additional nanoohms. Thermal dissipations are very low also. Repeated over about 16 000 cavities, however, requires a tremendous amount of cooling power to keep them at 1.8 K. That is why each cavity has to be meticulously polished and cleaned. So far, electropolishing followed by baking seems to be a very promising technique which reaches very high gradients... but unfortunately not every time. A stabilised production will be essential for the numerous ILC cavities. Materials physicists can help understand what the optimal experimental conditions should be. Another example is the delicate problem of the mechanical properties of niobium. How do you achieve the two contradictory requirements of an easily formable niobium which can also sustain the pressure from high vacuum conditions? Material scientists say that only a fully recrystallised niobium can allow forming of cavities with a high success rate. The mechanical strength of the completed cavities needs then to be adjusted through the design of strengthening rings. “The physics of RF superconductivity has been nearly unexplored over the past decades,” says Antoine. An understanding of the limiting phenomena requires theoretical work as well as very fine analysis techniques to look for the effect of tiny defects like grain boundaries, dislocations or interstitial atoms in this very thin surface layer. This very often requires techniques which are at the limit of what materials scientists can do, based on such such things as surface synchrotron radiations, X-rays diffractions, optical and electronic microscopy, and electrochemistry. “There are so many applied fields of physics related to cavity studies that we definitely need to work with these experts to benefit from their knowledge,” says Antoine. In future issues, NewsLine will publish more articles about niobium materials studies, starting with research at Argonne National Laboratory in early 2008. -- Perrine Royole-Degieux |

|||||||||||||

| © International Linear Collider | |||||||||||||