This is the second time I contribute an article for this column. Last April, I reported that we have entered the nanometre world by tuning the beam size just below one micrometre at ATF2, a test facility for the final focus system at KEK, Japan. Since then, there have been two experimental runs for one week each in May and December 2010, which were dedicated to the ATF2 beam tuning. I would like to briefly describe the achievements and our efforts until now.

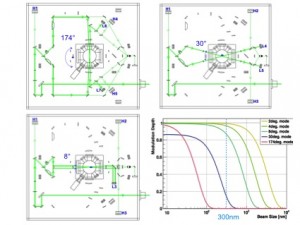

Figure 1. Configuration of angular modes in the interaction point beam size monitor and the range of beam size measurements.

The minimum beam size of 313±31 nanometres, was achieved in May last year. The beam tuning began with the initial setup of 850 nanometres and was brought down to 313 nanometres during a 16-hour experiment. The beam sizes were measured by the Shintake monitor or the interaction point beam size monitor (IPBSM). In the May run, we switched to a different mode when the beam size was successfully reduced to 313 nanometres for the lower limit in the eight-degree mode. However, we could not reduce the beam size further, since there is also another limit, the upper limit at the 30-degree mode. During the beam tuning, we observed that the minimisation of beam size required large rotations of the two final doublet magnets called QD0 and QF1 in several milliradians.

The figures show the laser crossing configurations for 174-, 30- and 8-degree modes and the modulation depth as a function of beam size. Wavelength, pulse duration and power of the IPBSM laser are 532 nanometres, eight nanoseconds and 1.4 joules per pulse, respectively. A laser beam comes from the bottom right corner, and is split into two beams at a mirror in the left centre. The crossing angle can be changed continuously from two- to eight-degree mode by fine adjustment of mirrors. The eight-degree mode can measure the beam size from 1,500 to 300 nanometres.

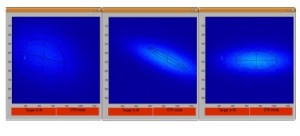

The ATF hardware is maintained and upgraded in every shutdown, especially the long summer shutdown that lasts about three months. In summer 2010, two old modulators at the 1.3-GeV injection linear accelerator were replaced with new compact ones. The beam lines from the radiofrequency gun to the damping ring were realigned. We realigned the final doublet magnets. One major improvement of the instrumentation is the installation of multiple Optical Transition Radiation (OTR) monitors with new targets at the diagnostic section just in front of the final focus system. The multi-OTR can measure the beam transverse profile by one pulse, whereas the present wire scanners measure it by scanning with many pulses. This significantly speeds up the beam tuning. One demonstration is shown in the bottom image, which has been taken during this autumn run from November to December 2010. The beam profiles clearly visualise individual corrections of dispersion and coupling.

Beam profiles at the OTR0X, one of four multi-OTRs; images before (left) and after dispersion (centre) and coupling (right) corrections. The multi-OTR system was made by colleagues at Valencia University and SLAC.

The ATF is operated with one-week cycle, concluding operations and starting again the following Monday evening. Two weeks in October were dedicated to the fast kicker study. Thirty bunches were successfully extracted with a spacing of 308 nanoseconds by the fast kicker from the damping ring where three trains of ten bunched beams at 5.6 nanoseconds were accumulated. It is a basic experimental verification of the beam extraction at the ILC.

The ATF2 beam tuning was conducted for five weeks from November to December 2010. The beam size was reduced to 2-3 micrometres in the vertical direction by tuning with a five-micrometre-diameter carbon wire (C-wire) at the interaction point. Improving the timing system with digital control, the IPBSM signals were tuned in two-degree mode in the fourth week. Also, the coupling correction and emittance measurement were done with the multi-OTR system for the first time.

During the last week dedicated to ATF2 beam tuning the beam was reduced to less than two micrometres with the C-wire. The beam size tuning brought the beam size down to about 370 nanometres. During the tuning with the six-degree mode, the modulation frequently reached to the maximum that indicated that the beam size became even less than 300 nanometres.

From 13 to 14 January 2011, the 11th ATF2 project meeting was held at SLAC, which was a week before the second Baseline Assessment Workshop. There were about 50 participants, and the whole meeting was operated with WebEx for remote participation. We reviewed the commissioning status of hardware and software and the continuous run with the nominal optics. We also discussed strategies for achieving a 37-nanometre beam size by 31 March 2011, the end of Japanese fiscal year 2010. We confirmed that the beam position monitor and multi-OTR systems were well calibrated and the ATF2 beam line was well modeled. Major issues are the large background in the IPBSM and the insufficient commissioning at the 30-degree mode.

Resuming the ATF2 beam tuning in February 2011, the beam operation became very stable with improvement of timing control system at the injection. Optical elements of the IPBSM were realigned in the most sensitive region for laser focus at the 30-degree mode, and the temperature control of the laser system was also improved for the stable laser beam generation. UUnfortunately a fire accident at the LINAC modulator stopped ATF operation on 16 February, but it will resume its operation this March with huge effort by the ATF staff and international support and encouragement of the KEK directorate.

I hope that I will report the achievement of a 37-nanometre beam size in the near future.

Recent Comments