Three researchers working on a detector for the ILC recently drove their components 1,500 kilometres from Arlington, Texas to Batavia, Illinois to get to know their detectors a bit better.

For approximately two weeks, researchers from the University of Texas at Arlington (UTA) sent muon, proton and pion beams through their chamber prototypes at the Fermilab Test Beam Facility, gathering data to see how they respond under different conditions. The chambers are made of gas electron multipliers, or GEMs. As part of the efforts of the CALICE collaboration, these detectors are being developed for the digital hadron calorimeter (DHCAL) to be used in future accelerators such as the ILC.

University of Texas at Arlington researchers Danrae Pray, Jaehoon Yu and Seongtae Park visited the Fermilab Test Beam Facility this month to characterise their GEM calorimeter chambers. Image: Jaehoon Yu

The UTA team’s four GEM chambers set up in the Fermilab Test Beam Facility. Three of these chambers are read out through 1-bit DCAL chip and one is read out through 13-bit KPiX chip. Image: Jaehoon Yu

The GEMs and electronics work together to recreate pictures of particle showers as they shoot through the calorimeter.

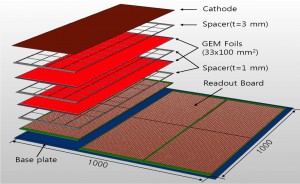

The UTA team chamber prototype is about the size of a slim stack of vinyl record albums – 30 centimetres each in length and width, a few millimetres thick. In their test setup, four chambers are stood on end, one close behind the other, facing the beam.

At one point during their tests at Fermilab, the UTA team got an unexpectedly large surge of protons.

“It didn’t kill our detectors – they were able to function as if nothing happened,” said University of Texas at Arlington’s Jaehoon Yu, who is co-leading the effort to develop GEM technology for DHCAL. “We can pulse it with very high-intensity protons, at least, ‘very high’ in our sense. These operators would laugh if I said 20,000 protons qualified as high intensity.”

GEMs use micrometres-thin copper-cladded plastic foils to amplify the electric signal when a charged particle such as a proton passes through the chamber. Two square GEMs foils, spaced 1 millimetre apart, are placed in the middle of the chamber. The rest of the chamber is filled with argon-carbon dioxide gas. When particles are sent through the chamber, they ionise the gas inside it. Thanks to the voltage that’s applied across the chamber, the electrons from the gaseous molecules head for the back of the chamber through the GEM foils. The electrons pass through the first foil, ejecting more electrons from the gas molecules that occupy holes in the foil. Those new electrons head towards the second foil, releasing an even greater avalanche of electrons. The newly multiplied electron population – about 10,000 times greater than the electrons released initially from the gas – is large enough to be read as a signal by electronic sensors in the very back of the chamber. That signal tells scientists when and where (and whether or not) a particle passed through.

The nice thing about GEM technology is the relatively small voltage applied across each foil – only a few hundred volts. That means it doesn’t take a lot of time for the detector to get ready to take on the next wave of electrons.

“It can recover fast from an avalanche,” Yu said. “That’s why these detectors can be used close to the beamline, where there are a lot more interactions.” With the detector’s quick recovery time, the chamber can accept a relatively high-intensity beam of charged particles.

For the ILC project, GEM technology is a complementary technology to resistive plate chambers, which use resistive glass plates rather than thin copper-clad foils to generate electron signals. It is a well-known technology, and as such was selected for initial exploratory technology for SiD (silicon detector) DHCAL. However, GEM technology is promising, and some LHC experiments are working on advancing it for their detector pieces.

While the gas electron multiplier amplifies the message that a particle has passed through, it works together with sensors to precisely describe the particle’s path. The UTA group has been working with two different chips to capture this electric signal from the chamber. One is digital (1 bit); the other is analog (13 bits). These chips are affixed to the anode at the very back of the GEM detector.

Three of the 33-centimetre by 100-centimetre chambers, seen on the left hand side, will be put together to make up 100-cm by 100-cm square detector plane. Image: Jaehoon Yu

The 13-bit analog chip, called KPiX, is being developed by Stanford Linear Accelerator Center National Laboratory in the US for the silicon-tungsten electromagnetic calorimeter for the ILC. KPiX was used in one of UTA’s four chamber prototypes. The current version of the chip can read out 512 channels, of which 64, arranged in an eight-by-eight square, are used for GEM chamber. The signal from this chip provides charge distributions measured by the UTA prototype.

UTA's 2-centimetre by 2-centimetre GIA (GEM image amplifier) chamber prototype, developed for medical imaging purposes, sits at the very back of the detector stack (inside circle). Image: Jaehoon Yu

“This charge distribution is beautiful,” said Yu. The high statistics data the team took with the KPiX chip agreed nicely with data from previous tests.

The digital sensor, used in the team’s other three chamber prototypes, is the DCAL chip developed jointly by Argonne National Laboratory in the US and Fermilab. Each chamber’s 256 active pads are read out by four of these chips (a total of 12 chips for the three chambers) for a finely grained readout of the particle’s path through it.

The UTA group put their chamber prototypes through a variety of conditions, varying the high voltage applied across each chamber; moving the chambers around relative to the beam to see whether their position makes a difference; determining, of the particles that actually pass through, how many are actually seen by the detectors. The multitude of tests filled their days.

“Since we want precision of about a percent or better, it requires a lot of events and therefore a lot of time,” Yu said.

The team is also testing a small prototype chamber (2 centimetres by 2 centimetres) developed for medical imaging purposes in the back of the detector stack. The protoype for this GEM image amplifier, called GIA, is the result of the collaboration with the University of Texas Southwestern Medical Center.

Over the next year the team will construct larger chambers, 33 centimetres by 100 centimetres in dimension, and put three of them together to make up 1-metre-square detectors. Thanks to this and many other efforts around the world, the GEM technology could be fully developed not just for fundamental physics but for applications such as X-ray imaging for astronomy, defense and medicine.

Learn more about DHCAL and GEMs.

Recent Comments