Beam lines, extraction lines, supply lines, final focus, sources, dumps, tunnels, shafts and not to forget the detector hall – the ILC’s central region is a busy place. In a recent technical review held at DESY in Hamburg, Germany, systems like the electron source, the positron source, the connection from damping ring to main linac, the beam delivery system and the machine-detector interface were under scrutiny. The main aim of these technical reviews is to find the best baseline design and a realistic idea of the cost for next year’s Technical Design Report (TDR). This one achieved even more than participants had set out to do: “We basically came out with a complete integrated design of the accelerator geometry, and how it fits in the tunnel,” says organiser Nick Walker, ILC project manager. “We hammered out the details and now we can work with a really realistic design much sooner than we expected.”

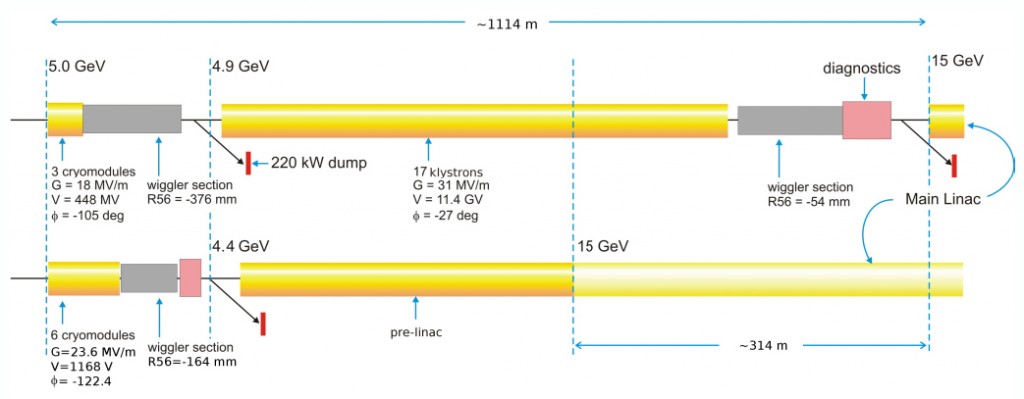

Another outcome is the decision to opt for a two-stage bunch compressor rather than a single-stage one. Bunch compressors sit between the damping rings and the particles’ racetrack, the main linac. They do what they say on the cover: they compress bunches, making them much shorter than they are when they leave the damping ring (nice and flat) and thus guaranteeing higher collision rates and more physics. When exiting the damping ring, the bunches are 6 millimetres long, and they have to be compressed down to the baseline 0.3 millimetres. The baseline design features a rather large compressor of almost a kilometre in length, consisting of an accelerator section followed by a section with wigglers. There have been efforts to compress the compressor, putting it all into one rather than two stages, partly because some of the parameters had changed from the Reference Design Report design, making a single stage possible, and partly because a shorter bunch compressor section would save a little money. However, participants decided that the two-stage bunch compressor with its larger possible compression ratio offers much more flexibility in the handling of the beam and a safety margin for the target luminosity, which couldn’t be outweighed by the cost savings.

Another big topic at the review meeting were the civil facility requirements for all systems that were reviewed, especially the interaction region. While the RDR offered only a very rough sketch of the hall where the two ILC detectors will sit in the famous push-pull configuration (one detector is pushed into the interaction point while the other is pulled out, letting only one detector take data at any time), it has now been decided that the hall must be roughly Z-shaped. The ends of the Z are the detectors’ “garages” while the central column is the interaction point. The next step is to decide how many shafts are needed and what their diameter should be – and what it would all cost, of course.

The central region review is the second ILC-wide review after one in Frascati, Italy in summer about damping rings. It had originally been supposed to be more than one, covering the sources and beam delivery system separately, for example, but the decision to pull these together into one review has turned out to be very productive. Next up are the two major ones: the superconducting main linac, under review at KEK, Japan, in January 2012, and civil facilities and siting, under review at CERN the following March.

Recent Comments