The current ILC superconducting radiofrequency (SCRF) cavity design is based on the so-called TESLA type (the elliptical shape as shown at left), a 1.3-gigahertz (GHz) nine-cell cavity. The design gradient has been set at 35 megavolts per metre (MV/m) and an average quality factor (Q0) of greater than 8×109 to realise the stable, long-term operation at 31.5 MV/m with a Q0 of ≥ 1×1010. The SCRF R&D plan has been scoping to realise a successful cavity production yield of more than 50% as an interim milestone, and to reach a successful production yield of more than 90% by the end of the Technical Design Phase. To evaluate the progress in view of industrialisation readiness, a standard process for cavity fabrication and surface preparation has been settled, following a technical assessment given by the Tesla Technology Collaboration.

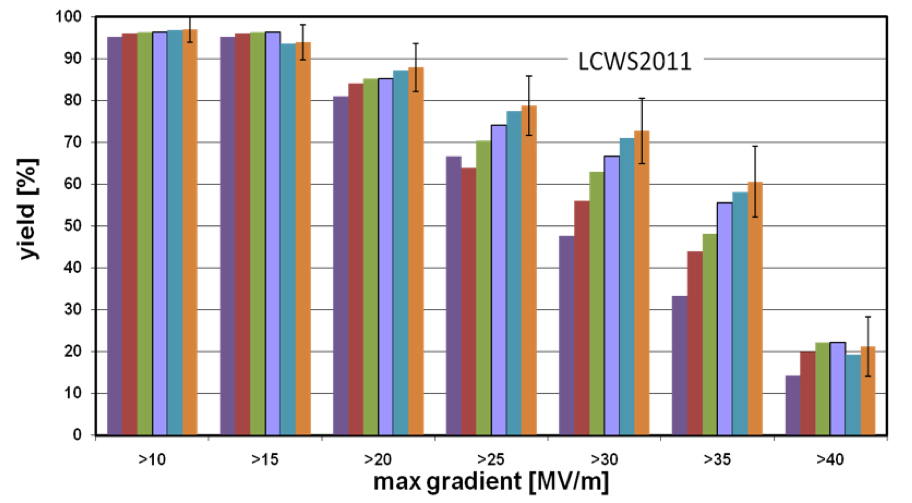

In the Technical Design Phase, we have established a clear definition of the production yield for a global database, adopting the yield measured after the first and second passes in the surface preparation process, after mechanical fabrication, as a rule for cavity qualification. The ILC cavity global-database team – consisting of members from Cornell, Jefferson Lab and Fermilab in the US, DESY in Germany, and KEK in Japan – took on the task of not only creating the database, but also defining rules for how the data should be included and how it would be presented. The figure below shows cavity gradient performance progress with production yield integrated over the period between 2006 and 2011. The first data-set was provided in October 2009, and the latest one in September 2011.

Cavity gradient performance progress with production yield for the second pass over the period between 2006 and 2011. The first data set was provided in October 2009 (violet) and the latest one in September 2011 (orange).

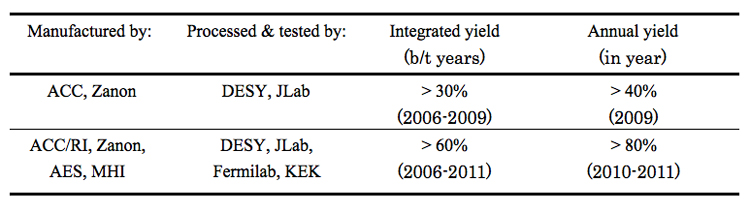

Progress in the production yield evaluation of nine-cell cavities for ILC SCRF cavity gradient of 35 MV/m

We now better understand how to improve the cavity gradient. For example, field emission has been much reduced thanks to new surface cleaning procedures such as ethanol rinsing and ultrasonic cleaning with detergent after the electropolishing (EP) process. A further reduction of field emission has been achieved by applying continued acid circulation during the EP process with a lower current density, resulting in keeping the cavity surface temperature lower. Optimised electropolishing and following streamlined cleanroom assembly guidelines resulted in a reproducible cavity process and hence reproducible cavity gradient results. As a result of the continued improvement of the cavity processing and better understanding of the gradient limit, the gradient goal of more than 90% yield at 35 MV/m and Q0 greater than 8 x 109 on average, allowing reasonable spreads, is being approached. Jefferson Lab is leading the way to reaching this goal with their own data set. The worldwide, general status in the production yield evaluation is summarised in the table to the right. Based on the recent decision to take a gradient spread of plus or minus 20%, we look forward to reaching the 90% yield as the SCRF R&D goal within the Technical Design Phase, and hence by the end of 2012.

Recent Comments