An SRF cavity entering the furnace where it will be baked with nitrogen or argon. Photo courtesy of Anna Grassellino

Like a jeweler hunting for a flawless diamond, for years, researchers have pursued purity in the niobium material used to make superconducting radiofrequency (SRF) cavities. But a team at Fermilab recently discovered that adding a bit of impurity may actually improve cavity performance.

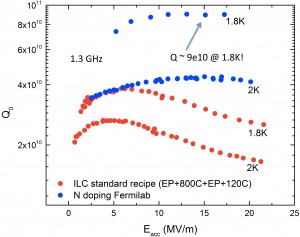

This year, a team led by Fermilab scientist Anna Grassellino found that baking niobium SRF cavities at high temperatures with gasses such as nitrogen or argon caused the cavities’ quality factors (Q) to double or triple and to increase with gradients, a phenomenon opposite to what had been seen in the past. Grassellino thinks this phenomenon may be due to nitrogen or argon atoms — impurities — that diffuse into the niobium. Introducing the impurities through such a bake may provide a way for ILC-type cavities to reach high Q at high gradient—enabling more cost-effective accelerators.

“It’s kind of interesting because, for many years, SRF has chased the idea of purity,” Grassellino said. “While it is true that purity of the niobium bulk is crucial for reaching high gradients, we are now discovering that you need a little bit of dirt at the very surface of the niobium cavity — the first tens of nanometres — to actually improve the cavity quality factor.”

Q refers to how well a cavity stores energy. If an SRF cavity has a higher Q, it requires less radiofrequency power to achieve a certain gradient. Gradient refers to the energy transferred to a particle over a certain distance. High Qs help accelerators save on costs needed for the machine’s cryogenics, or refrigeration, system, which is used to dissipate heat created by radiofrequency power. High gradients reduce costs by keeping accelerators compact.

In the past, cavity Q has been known to decrease as gradient is increased — a limitation known as medium-field Q slope. But Grassellino found that baking SRF cavities at 800 to 1000 °C with nitrogen or argon causes Q to increase as gradient is increased – basically a reversed medium-field Q slope.

The red data points show cavity Q decreasing with increased gradient, the “medium-field Q slope” phenomenon observed for standard ILC cavities in the past. The blue data points show cavity Q increasing with increased gradient, the reverse medium-field Q slope phenomenon seen after adding impurities. Image courtesy of Anna Grassellino

Grassellino came across this finding unexpectedly: She was hoping to use the high-temperature bake with nitrogen gas to convert niobium cavities to niobium nitride cavities. Instead of bonding with the niobium to form a new compound, the nitrogen atoms appeared to enter the cavity wall and take up residence in empty spaces in the niobium’s crystal structure — basically just foreign atoms in an otherwise niobium cavity. Grassellino saw the same effect when she baked cavities with argon gas.

Surprisingly, the impurities have a beneficial effect: The addition of foreign atoms appears to lower the surface resistance of the cavities, which in turn increases Q.

“As often occurs in the physics world, we accidentally found a cure for medium-field Q slope,” said Grassellino, who recently published a paper on the finding.

Of several single-cell, ILC-type cavities that Grassellino put through the bake, each reached a Q ranging between 3.5 x 1010 and 7 x 1010 at a temperature of 2 kelvins and a gradient of around 20 megavolts per metre. These Qs are two to three times higher than those of cavities treated with the standard ILC procedure. The same results were also achieved on a nine-cell cavity.

Increasing Q by adding impurities will be a big help for machines in which refrigeration costs are the main concern, according to Hasan Padamsee, former group leader of SRF at Cornell University.

“This treatment would have a big impact on a continuous-wave machine like LCLS-II,” Padamsee said, referring to the upgrade of SLAC’s Linac Coherent Light Source, a powerful X-ray laser. This type of machine requires high Q at medium accelerating gradients to keep refrigerator size, and costs, low.

“The gas-bake process is currently the best candidate treatment for achieving a Q high enough that LCLS would need only one cryoplant to cool it,” Grassellino said.

While achieving high gradient provides the most cost savings for a machine like the ILC, achieving both high gradient and high Q would be even better. In addition to refrigeration savings, increasing Q could lower ILC production costs by increasing cavity yield – or the fraction of cavities that meet the minimum Q – according to Anthony Crawford, a physicist in Fermilab’s Superconducting Materials Department.

“If the cavity Q is too low, then the cavity must be reprocessed or eliminated from the production stream,” Crawford said. Also, higher Q – less power dissipation – means lessening heating effects, which could significantly improve the cavity yield, thereby lowering production costs for the ILC linacs. Adding impurities at the very surface might turn out to be the key to do it.

Grassellino, together with Alexandr Romanenko from Fermilab’s SRF Materials Department and the lab’s Cavity Processing Group, led by Allan Rowe, are already working toward optimised recipes by playing with bake temperatures, times and partial-pressure regimes. A collaboration working toward the LCLS-II optimised recipe is ongoing. Matthias Liepe at Cornell University and Charlie Reece at Jefferson Lab lead those institutions’ participation in this effort.

“These findings already provide a better processing recipe for the many continuous-wave accelerators planned worldwide,” Grassellino said. “Once we optimise the bake parameters, we might score and basically end up with a recipe for high Q at even higher gradients, which might become the new recipe of preparation for the ILC cavities and other projects at the forefront of SRF technology.”

Recent Comments