Participants listen attentively at the workshop on linac operation with long bunch trains, held at DESY from 6-8 June. Image: DESY

For all the complicated engineering and hulking structures involved in operating particle accelerators, it’s the tiny, invisible particle beam at the centre of everything that is the machine’s reason for being. A probe for burrowing into subatomic places or a light to shine on molecular forms, the beam is science’s exploratory tool for the universe’s smallest, remotest corners.

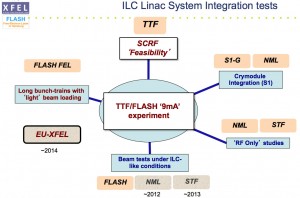

In their quest to make good, quality particle beams, researchers dissected the progress on this front at the recent workshop on linac operation with long bunch trains. The workshop, the second in a series, covered beam studies done for the International Linear Collider and for DESY’s Free-Electron Laser (FEL) FLASH and gave collaborators a chance to examine what’s involved in making stable beams composed of roughly millisecond-long pulses – the ‘long’ in ‘long bunch trains’.

Scientists presented the results of beam tests, called the 9-mA studies, performed in February. They looked in detail at how to tune the cavities for smooth timing and acceleration of the beam, methods to help prevent cavity quenching under the burden of so much power and modifying cavities’ quality factors to achieve the highest gradients.

“It’s about pushing the machine to its limits,” said workshop chair John Carwardine. “For example, we need to show that we can accelerate long bunch trains with the superconducting cavities running at full throttle. If things aren’t stable or you push too hard then you quench the cavities.”

There is strong synergy with the FEL programme in this regard. For the ILC, eking out the last few percent of energy from the cavities translates to significant cost savings, while for the FLASH FEL users, a few percent extra energy translates to shorter photon wavelengths and to potentially opening up new materials science experiments.

“The value of FLASH to ILC researchers cannot be overstated,” Carwardine said. As yet there is no other facility worldwide that can provide the kinds of beams needed for the ILC 9-mA studies. Long bunch trains are a fundamental advantage of superconducting technology for accelerators and are what distinguishes ILC, FLASH, and the European XFEL from regular-conducting machines. But it is only by operating the machine with the long bunch trains that scientists actually utilise the advantage.

“In the tests we tried to demonstrate what we could do in the control room, turning the knobs, versus what we showed on paper,” Carwardine said.

Other communities also find the beams useful, and nowadays more than 90 percent of beam time at FLASH is dedicated to operation as an FEL photon source, supporting scientists from a wide spectrum of disciplines, including those as diverse as molecular biology and solid state physics.

Energy stability requirements for FEL operation are a factor ten more stringent than for the ILC linac.

“Once you’ve set it up right, the beam is amazingly stable” said DESY’s Siegfried Schreiber, who is responsible for the operation of the German laboratory’s FLASH facility. “But you have to find this operating point. It’s tricky.”

Beams with long bunches require a good deal of power to get them moving. Even in the absence of a beam, the cavities need quite a bit. Once the beam is turned on, they need even more to sustain their face-value acceleration. Should anything happen to the beam during the machine’s operation – if the beam suddenly switches off – the extra power that gave it its boost now gives the cavities too much to handle, incapacitating the machine.

“Part of the challenge is actually managing the beam power and not losing it in the wrong places,” Carwardine said.

“You can literally weld holes in the vacuum chamber,” Schreiber said. Part of the future FLASH programme involves an upgrade of the present machine protection system that could also serve as a model for a linear collider.

For the ILC, the preferred beam current is fairly high as accelerator beams go. It’s made of trains of bunches of 3 nanocoulombs each zipping along 3 million times a second. The resulting current is 9 milliamps (mA), and in the 9-mA studies, ILC scientists perform tests at the FLASH facility to get a better handle on controlling this heavy load.

ILC research has benefitted significantly from studies on improving beam stability. Conversely, efforts in support of the ILC programme have had a payback for FEL user operation, especially given that more of the FEL users are requesting long bunch trains.

Schreiber estimates that about two-thirds of FLASH’s user community would have something to gain from high beam currents and long bunch trains. Adapting their machine to serve these groups means understanding the particular acceleration process.

“The better we understand the acceleration process, the better we can upgrade the hardware and controls to further improve the performance,” Schreiber said.

This has led to many accelerator improvements, such as a new, stable oscillator for providing power at 1.3 gigahertz, real-time integrated computing circuits for higher sampling rate and lower latency, and many other hardware upgrades so improvements to all FLASH’s cryomodules can be treated equally.

The workshop made clear that the mutual research benefits between the proposed collider that is the ILC and the test machine that is FLASH strengthens both.

“The machine is part of the experiment,” Schreiber said.

A third long bunch train workshop to address operating parameters for the next round of studies is planned for next year.

“We still have a lot of work ahead of us,” Carwardine said. “There were a lot of excellent presentations and some very good discussion during the workshop, which helps tremendously in understanding and prioritising what we need to do next.”

Workshop participants included scientists from KEK in Japan, Rutherford Appleton Laboratory in the UK, Argonne National Laboratory and Fermilab in the US and of course DESY. Global Design Effort project managers were also in attendance.

Stay tuned to future issues of ILC NewsLine to learn about some of the results presented at the second long bunch train workshop.

Recent Comments