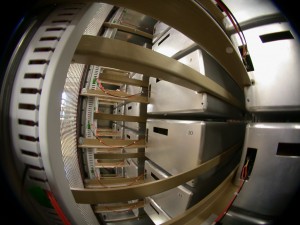

Alfred Viceral, Mark Kemp and Patrick Shen, who worked on the development of the Marx P2, stand in front of the enclosed modulator. One cell is pulled out of its drawer. Image: Ray Larsen

Last month scientists at SLAC National Accelerator Laboratory, US, ran tests on their latest power generator prototype. It met ILC specifications, delivering 140 amps of current at 120 kilovolts.

But the real test, the test of endurance, is still thousands of hours of run time away.

Researchers are developing the SLAC P2 Marx modulator, the power generator for the ILC, to be a hardier, higher-endurance version of its predecessor, the P1. Though the P1 worked fairly well, after a thousand hours of operation it revealed weak links in its design. With the P2, scientists aim to eliminate those soft spots.

“Reliability was the motivation for going to the P2,” said Mark Kemp, electronics engineer at SLAC. “We wanted to get rid of the single-component bottlenecks.”

Using lessons learned from the P1, researchers went with a more distributed-control approach to the P2. In the P1, much of the operation rode on the success of specific nodes. The P2 design has more redundancies – if one component gives out, another is there to take up the slack.

“The first prototype had more single-point failures in places where it could take the whole thing down,” said Chris Adolphsen, who runs SLAC’s power programme for the ILC. “This one is nicer. The redundancy is better, so it’s a little more robust in that regard.”

The Marx-type modulator delivers power using multiple cells. In SLAC’s first prototype, each cell contained two arrays of fifteen switches. In contrast, each cell of the P2 has a mere two switches. This simplifies control and protection of the cell.

Scientists also decentralised the circuitry responsible for propagating power pulses. Ideally, each pulse is held strong for its entire length, resulting in a pulse with a flat top. With the P1, scientists relied on one cell to finely regulate power from all the other individual cells. The scheme tended to produce pulses that were rippled on top rather than flat. With the P2, scientists gave each cell’s circuit card a piece of the pulse pie. The smart control system figures out the best way to shift and add up all the contributions from each cell just right, producing a sturdy, square pulse every time.

One cell of the Marx P2 modulator. In developing their second Marx modulator prototype, SLAC scientists outfitted each cell, or building block, with more system control capabilities. This approach increases the number of fail-safes in the system and therefore its overall reliability. Image: Ray Larsen

And if a component did fall short, scientists wanted the modulator to be smart enough to compensate for it.

“We wanted to increase its capability for diagnostics and prognostics – to have a control system that could predict when the modulator might fail,” Kemp said.

The control system tracks components’ performances over time so that scientists can note when a component hits a known benchmark of impending failure. The doomed part can then be switched out at the next opportunity.

The Marx P2 modulator contains 32 numbered voltage cells, each contributing up to four kilovolts of potential. Image: Ray Larsen

Though originally designed for the ILC, the SLAC P2 Marx has gotten the attention of other particle accelerator projects. CERN’s proposed CLIC collider is considering it for its drive beam, which generates its radiofrequency power. The future European Spallation Source to be built in Lund, Sweden, and KEK in Japan are also interested in using it to power their beams, as is Fermilab, US, for its injector linac upgrade.

Keeping in mind its potential for widespread use, SLAC researchers designed the P2 to be not only more reliable, but also to better lend itself to being manufactured in industry.

The choice of the P2’s cell voltage, for instance, is derived from state-of-the-art production in the semiconductor industry. Each of the modulator’s 32 cells is four kilovolts, a value based on a single die of silicon. Matching the cell’s voltage to semiconductor standards makes them compatible with chips produced en masse outside the laboratory.

“We’re trying to be less specialised in the components and the fabrication techniques,” Kemp said. “That lets us take advantage of the existing manufacturing capability.”

The scientists at SLAC also extended the characteristic topology of the Marx setup – the ramping up of voltage through many small steps.

“The Marx modulator is sort of like an Erector Set for power supplies – something with interchangeable parts,” Adolphsen said. By constructing the modulator, where practicable, with even more smaller parts, they designed one that was more easily manufacturable.

As Kemp points out, “It’s inherently easier to manufacture lots of little things than it is to manufacture a small amount of large things.”

In the future ILC, there would be 500 to 600 modulators, each delivering an average 130 kilowatts of power. Researchers designed the P2 to be more accessible than the P1: it fits well in the kamaboko-shaped tunnel being proposed by civil engineers in the Asia region. Further, it’s configured so people can easily get to its guts to perform maintenance.

SLAC scientists have begun the reliability tests of the P2. They’ll proceed for several months, obtaining data in time for the ILC Technical Design Report. They believe their smaller-parts and distributed-control approach will make the modulator significantly more reliable, an advantage not only for the ILC baseline, but perhaps for other accelerators around the world.

“We put a lot of development into the building block and the control strategy,” said Kemp. “It’s something we can straightforwardly massage to be in many different applications.”

Recent Comments