The cost estimate for the ILC that will accompany the ILC Technical Design Report (TDR) is intended to be a credible, comprehensive, and well-documented presentation of the costs associated with the ILC design as described in the TDR. To provide the cost information in a format which is useful for all regional partners, the estimate is a “Value” estimate, stated in “ILC Units” (ILCU) which are convertible to any regional currency, and in person-hours of institutional labour at the ILC laboratory, or at collaborating laboratories and institutions.

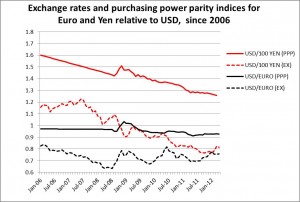

The first challenge for the value estimate is converting cost estimates from different regions and currencies into a common ILCU. For the Reference Design Report (RDR), the ILCU was defined as equal to 1 USD on 1 January 2007, and was related to other regional currencies (Euros and Yen) based on an average of exchanges rates over the preceding few years. However, in general, and particularly in times of wide fluctuations in monetary supplies related to financial crises, exchange rates do not necessarily represent true comparative prices between items manufactured in different regions of the world. International economists have introduced the concept of “purchasing power parity” (PPP) to deal with this issue. Compiled through extensive surveys by the research arm of the Organization for Economic Co-operation and Development (OECD), PPP indices are price relatives that show the ratio of the prices in national currencies of the same good or service in different countries.

Thus, for the TDR, the “2012 ILCU” will be defined as equal to 1 USD on 1 January 2012, but the relation of the ILCU to Euros and Yen will be based on PPP indices (as of January 2012: see figure above). The use of PPP indices, while not entirely free of difficulties, offers the best way to state the TDR estimate as a region-independent value estimate. It also provides regional users of the cost estimate, seeking to assess the local resource requirements for in-kind contributions, with a way to translate components of the estimate into local currencies which is not dependent on exchange rates.

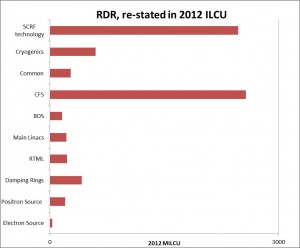

ILC Reference Design Report cost, re-stated in 2012 ILCU. The costs for the area systems are for conventional technical systems only. Image: 2007 ILC RDR

With this definition of the 2012 ILCU for the TDR, the RDR estimate can be re-stated in these units by escalating the elements of the RDR cost estimate from 2007 to 2012, based on regional escalation indices, and converting to 2012 ILCU. The resulting breakdown of the escalated RDR is shown in side figure. This would be the TDR estimate if the TDR design and cost basis were identical to that of the RDR.

Of course, there have been major changes to the RDR design since 2007, which have resulted in a TDR design which is more cost-optimised. In addition, R&D and design work since 2007 has improved the scope and reliability of the cost basis. New and more detailed site designs and cost estimates have been developed for the conventional facilities in Asia, the Americas, and Europe, with more extensive use of contractor estimates than was possible for the RDR. New designs for the L-band high-level radiofrequency (RF) modulators and pulse distribution systems have been developed, and new estimates are available for the multi-beam klystrons. Much experience has been gained throughout the world in cavity fabrication and processing, and in cryomodule fabrication and assembly, in particular for the European XFEL. The net result of all this new information is that we expect about 70% of the TDR cost estimate to have a new cost basis. For the remaining 30%, we will use the RDR cost basis, with quantities modified as appropriate based on the TDR design.

For the TDR, the conventional facilities design in each region is adapted to the specifics of each regional site. Differences in site characteristics and constraints have led to rather different designs for the conventional facilities (and for some of the technical systems) in Asia, as compared to the Americas and Europe. These design differences naturally have different costs, which poses a problem, since the Global Design Effort goal is to produce a single cost estimate for the TDR. This single estimate will be an average of the estimates from the three regions; the sources of the variance from region to region will be clearly explained in the TDR.

The technical progress in cavity and cryomodule development since 2007 has been enormous, which naturally leads to an improved understanding of the costs. In addition, experience from the construction of the European XFEL, now underway, provides an invaluable source of cost information. However, the ILC project has substantial scale, and the numbers of superconducting radiofrequency (SCRF) components required are much larger than for any previous project. Economies of scale in the production of these systems must be exploited to manage the project costs well. To estimate these economies, we have initiated a number of industrial studies (at least one in each region) with firms which have experience in cavity fabrication or in mass production. These studies are not yet complete, but the preliminary results indicate that substantial reduction in the unit costs, even from those for European-XFEL-scale quantities, are possible.

Adoption of a realistic model for the procurement, acceptance and testing of elements of the superconducting technology is also a key issue. The model must be consistent with the vision of the project as a world-wide collaboration incorporating in-kind contributions from industries and laboratories in many regions. The model must also strike the proper balance of risk reduction versus cost mitigation. The way in which these general principles are realised in a specific procurement model for ILC SCRF components will be developed over the next few months.

At a more technical level, there will also be major changes from the RDR. All elements of the TDR estimate will be formatted in custom-designed Excel spreadsheets which are created by a set of Windows scripts called the ILC Cost Estimating Tool (ICET). The custom spreadsheets contain all the cost information, including uncertainty estimates, and each line item of the estimate can be tagged and linked to basis-of-estimate documentation stored in EDMS. ICET creates a cost-WBS structure from the input spreadsheets, and also allows the estimate to be loaded into a database. Reports can be run on the database to detail the estimate by cost-WBS element, and cross-cuts can also be generated using the line item tags. These features, together with the links to the detailed basis-of-estimate documents, are intended to make it as easy as possible for future reviewers and users of the estimate to obtain detailed project cost information.

Recent Comments