After nearly a year of campaign and some 10 weeks of data taking in various beams at CERN and at DESY, the detector layers, absorbers, support structures and electronics of several calorimeter prototypes for a future ILC detector are back in crates and on their way to DESY and other labs in Germany, Japan and the US. 25 people have more than 15 million events sitting ready to be analysed. The calorimeter test beam campaign is over – and it went very well, the researchers say.

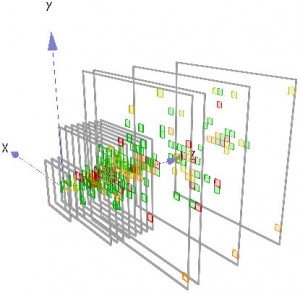

One of the aims of the tests was to thoroughly understand the time structure of hadron showers in the calorimeter to cross-check against simulated data, compare absorber materials and extrapolate to a full-scale detector. The speciality of the ILC calorimeters will be their particle flow algorithm, the possibility to reconstruct and identify every single particle in the detector. The detectors are designed in such a way that the telling apart of individual particles and measuring their energy is made easier by making them extremely high-resolution camera equivalents with a huge number of channels.

One speciality is the energy measurement of so-called jets, cones of secondary particles produced in the calorimeters after a collision. In order for the energy measurement to be complete, all constituent particles need to be added up. Sometimes, depending on the material they are produced in, some of them – neutrons – are slower than others and could be mistaken for particles belonging to another event. Having the time information from the more than 3000 active cells provides the researchers with a lot of detail, and checking this data is one of the central outcomes of the test beam campaign.

Having all these channels also has a downside: information somehow needs to get from detector to researcher. This posed another challenge: integrate electronics and cables into the prototype in such a way that it could in principle form a part of a bigger, complete particle detector. In a test beam there is a lot of space, but in the real thing, every square millimetre counts. Katja Krüger, test beam coordinator from the German lab DESY, points to the layers of hadronic calorimeter with their electronics neatly hidden inside: “There’s only one ethernet cable coming out of the setup. And that’s even though this one-cubic-metre prototype has about as many channels as a third of the hadronic calorimeter of CMS.” And these channels make up only a fraction of the channel number for the final hadronic calorimeter in ILD

For the four weeks spent in the CERN SPS test beam in summer the CALICE team used a common data acquisition concept. “The data acquisition is new and palpably faster,” Krüger says. All calorimeter types, use the same data acquisition, making the reconstruction of particle information smoother.

The CALICE collaboration ran the last comparable campaign in 2006/2007, so it was time for a load of new data and new experiments. This time, in the analogue hadronic calorimeter alone, 27 boards with 144 channels each were tested with two different absorber materials, steel and tungsten, using different types of photo-sensors. Analysing and interpreting all the information is the team’s job for the next month. “Our list of things to develop and find out is definitely getting shorter,” says Felix Sefkow, former CALICE spokesman who was heavily involved in the campaign. “Having solved a fundamental component like data acquisition makes for a big item ticked off our list.” “It all helps pave the way to a full prototype that we’re aiming for in 2018,” adds Frank Simon from the Max Planck Institute for Physics in Munich, Germany, and spokesman of the CALICE collaboration.

Test beam setups usually consist of a couple of active layers, electronics, cables going in and out, and excited physicists. This particular one also featured a rather rare component: a beer chiller. It wasn’t there to help students through the night shifts, however: it kept the electronics on the outside of the calorimeter prototype at a constant temperature. Why a beer chiller? It is cheap, does not use a lot of electricity and fulfils its job reliably because it’s simple and only does one thing: cool, explains project engineer Karsten Gadow from DESY, father of the idea to use beer technology for particle physics.

The CALICE chiller is in fact recycled from a previous experiment at DESY, the “Very Forward Proton Spectrometer”, part of the former H1 detector at the HERA accelerator. “I needed something that was radiation hard and could keep electronics at precisely 18 degrees. On my way to work I used to pass by this air conditioning company that also equipped pubs from time to time, and one day I put two and two together,” Gadow says. The chiller only fulfilled its designated function (to cool beer, that is) once: at the shutdown party for HERA.

Recent Comments