“We are just standing at the entrance, and our world efforts need to continue or become even stronger.”

These are the words Kaoru Yokoya used to close his ILC Newsline Director’s Corner at the end of last year. (The italics are mine.) Six months later his words continue to ring true and are perhaps a bit more urgent. We now have to ask how to make world efforts continue and become stronger.

The pressure we feel now, in mid-2012, is to finish the primary Global Design Effort (GDE) deliverable – the Technical Design Report (TDR). When completed, the TDR will represent the conclusion of a successful design and R&D programme, something remarkable in itself. We are obliged, of course, to put together the programme that will take us through the entrance, TDR in hand. This programme will fill the gap left behind when the GDE completes its mandate.

As we near the end of the Technical Design Phase, it is time to ask what has been accomplished and what remains to be done. The presentation of Satoru Yamashita at KILC12 in Daegu, Korea, summarised in the Director’s Corner a few weeks ago, outlines what is needed to prepare the project – from a project perspective. In my Director’s Corner this week, I would like to look to the other side – the technical side. With the writing and editing of the TDR text well underway, it is quite timely to do this.

From the start of the Technical Design Phase, in 2007, we formulated and laid out a comprehensive R&D plan with agreed-upon goals and a rough timeline. This was a vital step towards the creation of the GDE R&D team – especially the definition of practical, but still quite challenging, targets. The importance of beam test facilities and cavity processing and test infrastructure was, of course, clear from the start.

At the end of the TDP, three beam test facilities are in operation, CesrTA at Cornell in the US, ATF at KEK in Japan, and FLASH/TTF at DESY in Germany, and two new facilities are coming online, Quantum Beam/STF at KEK and ASTA/NML, at Fermilab, US. On the infrastructure side we have the cavity mass-production and cryomodule assembly just getting started for the European XFEL and the nearly-complete renewal of the well-worn Jefferson Lab cavity processing system in addition to the proven fabrication, processing and test system at KEK and the similar system at Argonne and Fermilab.

What do we have to show for these investments? And what remains to be done? Critical TDP goals have been met but for one notable exception. Using CesrTA, we have developed models, tested them, and demonstrated vacuum chamber designs that will be quite effective in mitigating the electron cloud instability. The CesrTA electron cloud team will publish their report later this summer. Much of what has been learned will be applied in the future Super B-Factories. The CesrTA group will continue to test the performance of the mitigations and will be able to assess the long-term durability of coatings and key vacuum chamber features.

Main linac system testing with beam was deemed important enough to warrant test facilities in each region. These are naturally coupled with the nearby fabrication, processing and assembly facilities. The main linac is an ILC ‘cost-driver’ and a key element of the system test is value engineering. As we move forward, we expect to gain better understanding of production strategies and costs. FLASH/TTF is most advanced, by far, and beam tests done there have validated the SCRF technology parameters chosen for the ILC (read also this story in ILC NewsLine). Going forward, we plan to characterise operation and control at the highest practical gradients and beam currents.

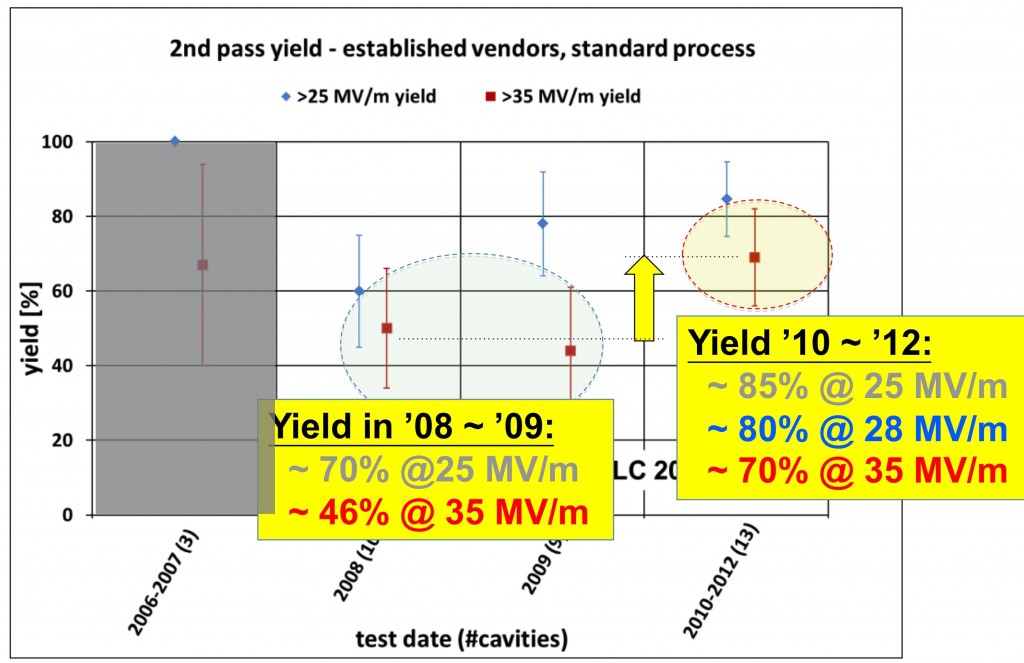

The most visible superconducting radiofrequency performance target has been the ‘cavity production yield’, set to achieve 90% by the end of the TDP. The graph below, shown at the Project Advisory Committee (PAC) review last month, shows our progress towards that goal.

Progress towards 90% production yield for cavities with an average gradient of 35 megavolts per metre (MV/m).

One of the most positive performance advances seen during the TDP are the very high cavity gradient test results of around 42 MV/m. This led us to allow a spread of cavity gradients for the TDR baseline, i.e. cavities with gradients between 28 and 42 megavolts per metre (MV/m) will be accepted for assembly in to cryomodules, giving an average gradient of 35 MV/m as required. The yield of such cavities in 2010 to 2012 is 80%, as shown in the figure, and further work will be done to better understand and improve the remaining margin.

ATF2 is the last on my list. It is the notable exception mentioned above, and it is at ATF2 where serious work towards TDP targets is still underway. Importantly, ATF is the only test facility where beam size has been agreed upon as the goal. This means that the ensemble of beamline components, such as magnets and instrumentation, and their alignment and positional stability with respect to each other has to be correct. In addition, a specialised beam tuning procedure has to be developed and has to show effective convergence so that related issues can be studied. With a target vertical beam size less than 40 nm, there is little margin for error in the overall scheme. The ATF2 team reported their status at KILC12 meeting last month: 169 nanometre.

As I prepared this Director’s Corner, the GDE announced that Lyn Evans of CERN has agreed to lead us forward, through the entrance that leads to preparation of a proper project. With positive anticipated results from the Large Hadron Collider and a strong positive push from the physicists who will use the ILC, along with the publication of the TDR, we are on our way.

Recent Comments