CLIC is one of the potential follow-up projects to the LHC, alongside the International Linear Collider and the Future Circular Collider studies. Instead of smashing protons into protons, it would collide electrons with their antiparticles, the positrons. And instead of bending the particles around a ring, CLIC would be a 50-kilomtre-long straight line using a unique acceleration technique of one particle beam driving another like a gigantic power converter. The project published its Conceptual Design Report in 2012, proving that the technologies they plan to use for their ultra-precise machine are working, and is now in a project preparation phase where these technologies are tested, improved, made more efficient and more reliable and where physicists and engineers take a closer look at the cost of the individual components. All this is where the new module comes in.

It’s the first module that is integrated into the test facility and has all the functions of future CLIC modules. Many of the different techniques and technologies needed for CLIC’s sophisticated drive-beam acceleration, where one beam of electrons pushes another by transferring its energy, have been tested individually in the past. The CLIC researcher have proven that they can generate the high-current drive beam, that they can accelerate it and slow it right down again for the energy transfer to the main beam, that the beam can have the designated gradient and quality and that the energy from the drive beam can actually be transferred to the main beam at the right frequency through the power extraction and transfer structures. They also showed that the accelerating structure can reach a gradient of 105 MV/m at a pulse length of 240 nanoseconds and a low breakdown rate in separate high-power tests.

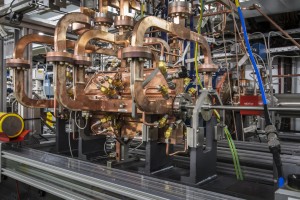

Now they’ve put it all together in the prototype module, added CLIC-type alignment systems,accelerating structures with higher order mode damping, integrated diagnostics tools like wakefield monitors and are testing it with beam. “It’s a complex system, and our very first experiments look promising,” says CERN’s Steffen Doebert, who is part of the team that developed the module. “We have to check all the connections and calibrate the module before installing a second super accelerating structure consisting of two accelerator units.”

The two super structures will be installed on the same girder and then tested with beam (another two modules are being built and will be tested without beam). With the help the diagnostic tools integrated into the module, which can detect very small fields, the scientists know where the beam is at any time within the structure, and can make beam based corrections thanks to a very precise alignment system developed by the CERN metrology group and a silicon carbide support that can be adjusted in all directions. “After all we need to be precise down to ten microns,” says Doebert.

The module development has been a large effort within the CLIC collaboration with contributions from outside institutions and CERN groups. They meet from 26 to 30 January at CERN for their annual collaboration meeting.

This story was first published on the CERN website and the CERN Bulletin

Recent Comments