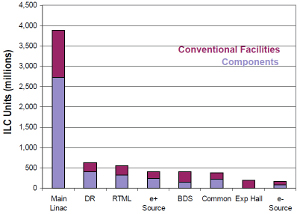

The distribution of ILC subsystem value estimates for the reference design in ILC units (2007 US dollars). Note that the costs are dominated by the main linac and conventional facilities.

For a very large potential project like the ILC, costs are obviously a very big issue. Reliably costing such large projects with ambitious new technologies, in advance of having a detailed technical design and implementation plan, is a real challenge. In addition, costing is done differently in different countries, making it particularly difficult to provide costing information that can be reliably used around the world. For the ILC 2007 Reference Design Report (RDR), we used a so-called ‘value’ estimate, a scheme independent of any particular accounting system but, in principle, compatible with all of them. The VALUE methodology is becoming a standard for large international projects.

Briefly, as discussed in the ILC RDR: “The ILC estimate consists of two important parts: VALUE (in terms of currency units) for items provided and LABOUR (in terms of person-hours or person-years), which may be provided by the collaborating laboratories and institutions, or may be purchased from industrial firms. (…)The value of a component is defined as the lowest reasonable estimate of the procurement cost in adequate quality, based on production costs in a major industrial nation. (…)The labour is defined as ‘explicit’ labour, which may be provided by the collaborating laboratories and institutions, or may be purchased from industrial firms.”

The costing as produced for the RDR is a very good starting point for the new costing for the Technical Design Report (TDR). The first Global Design Effort (GDE) meeting to initiate the TDR costing was held at Caltech, US, immediately following a face-to-face Executive Committee meeting in July. There we discussed how to begin from the RDR value estimates and produce the most reliable updated value estimates, taking into account the changes in design, new information on component costs and some better information on how we propose to build the ILC through a global collaboration. We have built some new tools to help with the costing, which include having technical information in an electronic document management system at DESY and the development of a costing tool, called ICET.

The purpose of the Caltech costing meeting was to discuss and agree on the strategy for TDR costing. We agreed that the main focus will be on the big cost drivers, conventional facilities and superconducting radiofrequency systems in the main linac. The costing guidelines will follow those of the RDR, facilitating comparisons. The meeting covered a broad range of issues, but special emphasis was placed on conventional facilities estimating, including a case study from the recent ILC Asian siting studies, as well as a discussion by Akira Yamamoto, GDE project manager, on preparations for industrialisation of main linac components.

One interesting point of discussion involved how to compare current estimates to older RDR costs. In addition to the technical changes and new information, there has been escalation since 2007, as well as large changes in exchange rates. In addition to escalation from 2007 US dollars, at the time of the RDR in 2007, the exchange rates were 1 US dollar = 0.833 euros = 117 yen (based on average rates over 2003-2007). The exchange rates in August 2011 were 1 US dollar = 0.696 euros = 77.1 yen. These large differences have motivated us to consider how best to make the conversions from 2007. For example, the Organisation for Economic Co-operation Development produces an alternative based on a measure of relative regional purchasing power parity (PPP), which has more stability. This conversion system may be more reliable for producing technical equipment in different countries for the ILC and we are investigating whether to adopt it.

We have been very cost-conscious in evolving the ILC design and in developing our key technologies. We have tried our best to contain cost growth in the process. We use a necessary feedback system in which cost information is used to make the design more cost-effective. Over the next year as we develop the technical design and value estimate for the ILC, we will also want to make sure we have enabled the points of comparison with the Compact Linear Collider Study (CLIC) costs. I will report more on TDR costing as it develops, but we will not report any actual cost numbers until the value estimates are completed near the end of 2012.

“…development of a costing tool, called ICET.” Really?

“‘He’s not your everyday-type prankster’ / I’m Ice T, the original ganster!’

-PT