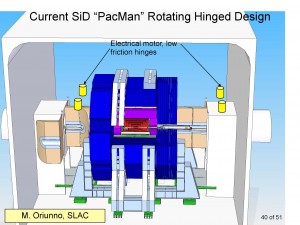

A slide from the machine-detector interface talk at this week’s SiD meeting. It shown the so-called PACMAN shields in the interaction region between the detector and the beam tunnel.

One of the challenges involved in an international project is that of maintaining good communication among the collaboration members. While the detector community has learned over the years to adapt to this situation, typically accelerator design has been centred at a host laboratory that provided the technical leadership. The ILC design team with its global structure has required a different approach. Communications technology has advanced enormously during the past decade and the use of electronic meetings is now routine (even though time differences remain a more fundamental problem as attested to by the many late nights of our Japanese colleagues and early mornings on the west coast of the US). Certain cross-cutting issues however are still best dealt with via face-to-face interactions and this is where the linear collider workshops such as the LCWS series prove their worth. Since the time available at these workshops is finite thorough preparation is the name of the game.

Just like the Ada bridge in Belgrade, where the next linear collider workshop will be held, links two municipalities, the worksop will address cross-cutting issues between accelerator and detector. Image “Ada vatromet 1” by Littjo – Own work. Licensed under CC BY-SA 3.0 via Wikimedia Commons.

There have been two main themes to the recent ILC work: technology development and a site-specific design. While not ignoring the former issue, our next global meeting, LCWS 14, which will take place from 6 to 10 October in Belgrade, Serbia, will emphasise the latter. A site-specific design is necessary to establish the machine footprint which in turn allows the conventional facilities and siting (CFS) design to proceed. The machine footprint not only involves details of each component of the accelerator chain but also the detector hall layout, tunnel penetrations and tunnel cross-section. I’m sure that we all agree it would be a good idea for the two beams to collide in the centre of the detectors. For most machines this is easily accomplished by adjusting the relative phasing of the opposing bunches. For the ILC it is not quite that straightforward. In order to provide the polarised positron option the high-energy electron bunch is used to provide polarised photons on the positron production target. This design feature results in a fixed time difference between the electron and positron bunches. The collision point position is then given by the path length of each bunch as determined by the fixed machine geometry. Small adjustments are possible in the damping rings but the overall machine footprint must be calculated (and constructed) to within a tolerance of several metres. Since the path length involves interaction among all of the accelerator subsystems, LCWS 14 will be used to address this topic. The length of the main linac is part of this overall path length equation but in addition, together with the average accelerating gradient in the cryomodules, it will also determine the collision energy. Decisions must be made carefully.

A major factor in determining the layout of the tunnel cross-section is the radiation shielding requirements. Plan for too much shielding and the cost increases, plan for too little and operational factors can limit the luminosity. In most parts of the machine, the shielding layout is determined by the so-called worst-case accident scenario. Defining these scenarios will be a topic for discussion during our time in Belgrade for all of the sub-systems.

One topic that has received major attention since the last workshop is that of the Detector Hall layout. Steady progress has been made by the CFS and machine detector interface (MDI) working groups and hopefully a consensus approach will be established next week at Ichinoseki during the MDI-CFS Meeting on ILC Interaction Region Issues. We anticipate that LCWS 14 will provide the forum to allow a final review by all the interested parties before adopting the new design into the baseline.

The formal process to ratify design changes into the ILC Technical Design Report baseline has been agreed upon by both the accelerator and physics & detector communities. A change request will be generated by the appropriate group. This change request will cover both the technical and cost impact of the proposed modification. It will then be approved (or not) by the change control board and the appropriate baseline documentation updated. In this way the site-specific design will start to take evolve from the TDR framework. The Belgrade workshop will be the start of this next phase in the design.

Recent Comments